Feature Spotlight Series: Bar Code Labeling

This Feature Spotlight blog series takes a deep dive into various features available in AIM’s ERP software solutions, AIM Vision and AIM AutoCOR. Today’s Feature Spotlight blog focuses on bar code labels, a standard requirement for world-class ERP solutions, especially in the automotive industry.

In any manufacturing setting, bar code labeling delivers automated accuracy and streamlined efficiency – in the automotive industry, bar code labeling is a critical requirement that helps suppliers to comply with ever-changing customer mandates.

The benefits of using bar codes are essential to succeed as a 21st century manufacturing operation. Bar code technology:

- Eliminates opportunities for human errors/typos

- Improves inventory control

- Provides accurate data in real time

- Injects flexibility into operations

- Reduces training time for workers

Let’s break it all down.

Types of Labels

AIM Computer Solutions offers all versions and types of labels required to properly track material and items as the plant receives them, sends them through manufacturing processes and ships out finished goods, complying with customer needs and requirements.

AIM bar code labeling applications include embedded business logic for more than 450 OEM and sub-tier trading partners with more than 1,800 AIAG standardized bar code label formats. Whenever OEM customers update label requirements or formats, add new trading partners, or revise certificate of origin forms for the USMCA agreement, AIM Computer Solutions issues service pack updates.

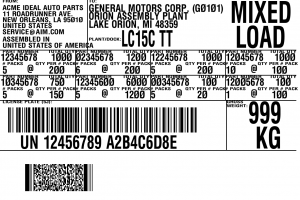

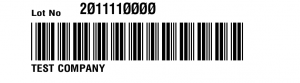

- Container or Serial Label: A Container or Serial label is placed on a container of a unique part or finished good. The container label includes details on the supplier, ship to location, part, quantity (which is commonly the standard pack quantity), and various reference data as mandated by the customer.

General Motors Container Serial

- Master Label: A Master Label is usually placed on a pallet or container that contains several Serial Labels for the same Destination or Customer Part Number. The quantity on the Master Label reflects the total quantity for all Serial Labels. Master labels can be created by scanning Serial labels using a tablet app in real-time on the plant floor, auto-created with the shipper build or created when printing a batch of serial labels.

Ford Motor Master Label

- Mixed Load Label: A Mixed Load Label is usually placed on a pallet or container that contains several Serial Labels for the same Destination, but for multiple Customer Part Numbers.

General Motors Mixed Load Label

- Part Label: A Part Label contains unique identifying information for a part, such as the item number and lot number.

Sample Part Label

- OEM-specific Labeling: Among the OEM-specific labels integrated with AIM solutions are GM multi-language labels such as 1216 labels, Honda-compliant Line-Side labels, Toyota-compliant One-Way Kanban Labels, Outside Process Parts (OSP) program labels for L&L Products and more.

L&L OSP Program Serial for FCA

Tesla Individual Receive Label

- Hazardous materials labeling: Customer-compliant labeling often requires hazardous material or those items requiring caution/safety to be identified with the inverted triangle and circle symbol. AIM’s Safety Item field identifies safety-related parts.

- Quick Receive Label: The Quick Receive Label Print for Honda Shipments is applied by Honda suppliers at the time of shipment. Honda Receiving associates scan this label to receive product information into the Honda system. The label identifies the contents of an entire pallet and includes ASN Number, Project Number, Honda Production Lot Number, and Ship To Address. This label is required on every pallet, stand-alone box, rack, basket, cart, etc.

- Vendor-supplied material labels: The AIM solution easily tracks vendor-supplied material labels.

- AIM-affixed Raw Material Label: These labels are affixed at the point of receiving.

- Production Container Label (lotted or non-lotted): Crucial Production Container Labels provide checks for traceability and quality assurance. See Traceability, Lot Control and Quality Assurance article.

- Outside Processing Labels: The container labels with the item number and quantity make quick work of building an outbound processing shipper and can be scanned when product returns from processing.

It Starts with Receiving

When raw material and purchased parts come into the plant, users launch the AIM Mobility Receiving App or Bar Code Receiving module to scan, label and enter every item into the ERP solution database. Users scan inventory receipts from suppliers and vendors via bar code labels. The app promotes an improved workflow, delivering a streamlined inbound receiving process based on bar code scanning.

Sample Receiving Lot Label

Operators use the AIM Mobility Bar Code PO Receiving application to receive raw materials and purchased parts on the receiving dock via a tablet and scanner. They can review the receipt, check for exceptions, and post the receipt into inventory. With the Barcode PO Receiving utility, users can uniquely identify each container and immediately assign a lot number upon receipt.

Production / MES / Operations

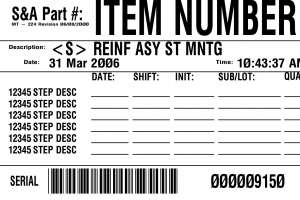

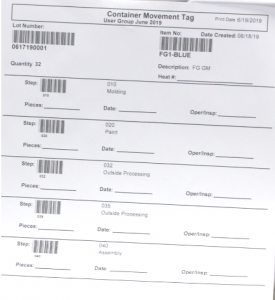

The manufacturing execution system uses the bar-coded production tags to track lotted material throughout the entire production process.

Sample Production Routing Label – generic

The system creates line-side labels during production, which eliminates the need for re-labeling and prevents mislabeling. Users can print line-side shipping labels at the packaging workcenter and the manufacturing workcenter during the last process step.

The AIM-generated tags, labels, and paperwork with bar codes make it easy to conduct a physical inventory of items to identify and track product on the floor.

Sample Production Container Tag

Updated bar code labeling and options, such as daily end-to-end inventory transactions, give users complete traceability and detailed lot tracking.

Bar code labels give complete transparency into product movement through the manufacturing processes, from raw materials through finished goods.

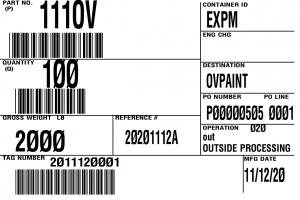

Outside Processing

Bar coded technologies can be used when shipping WIP material to an outside processor. Users create one bar code label per container being shipped to the outside processor. These container labels can be scanned to build the shipper. When the material is received back from the outside processing vendor the containers can be scanned again during the receiving process.

Sample Outside Vendor Container Tag

Shipping

Bar code labels simplify the entire shipping process for manufacturers. OEM-compliant bar code labels are an essential component of the automotive supply chain. Customers send EDI with daily ship quantities. These documents also contains specific details related to unloading points (line feed location and dock code), and special shipping data needed on ASNs and product package bar code labels (RAN #, Manifest, Kanban number).

All data and label contents from EDI transactions go into the AIM Orders module and are printed on bar code labels, according to customer requirements. AIM Vision and AIM AutoCOR automatically gather unique data from the inbound EDI transmissions. The Order Management application stores this reference data for use in the AIM Bar Code application for use on container and pallet bar code labels, and in the Shipping application to include it on shipping paperwork and the ASN, as mandated by the OEM/customer.

AIM ERP solutions include pre-set label definitions for all trading partners, with more than 1,800 bar code formats available, so that you can easily ship customer-compliant labels to all your customers.

Operators can automatically create labels as a part of the ship order process and scan all labels of a shipment during the staging process to ensure every order is complete and correct prior to processing the shipment.

Using the AIM solution, operators can auto-create and print labels with flexible label creation methods based on shipping requirements, print line-side labels during the production process, or create and print labels on demand. The system easily handles special integrations for OEM systems, such as the Toyota Shipping Confirmation System.

Using the AIM Mobility Shipping app, operators create master bar code labels from staged container serial labels, work with labels from scanned ship orders and verify exceptions while updating the order and printing the shipping paperwork. The AIM Mobility Shipping app delivers real-time access to all relevant shipping information from the bar code labels, including a list of available shippers with shipper number, destination code, shipper date and time, and destination name. Each shipper shows part data, including shipper line number, customer part number, container ID, ship and pack quantity, number of containers to ship, and number of containers already scanned.

Inventory Control

Bar code technology promotes complete traceability and detailed lot tracking, reducing the need for physical and cycle counts or making them less time-consuming. Using bar code scanning with mobile apps delivers efficiency. Operations improve and customer satisfaction grows when manufacturers meet or exceed production schedules by delivering on-time products aided by accurate inventory management. Using bar code technology gives manufacturers the tools to:

- Track inventory transactions in real time

- Manage lot traceability

- Perform physical and cycle counts quickly and accurately

- Track warehouse inventory at location levels, identifying all movement of raw materials, WIP and finished goods

- Control product and process modifications/engineering changes

- Enhance customer experience

The AIM Mobility Physical Inventory app scans bar codes so users can perform physical inventory counts with a tablet and scanner directly on the plant floor. The app delivers efficiency minus the error-prone, hand-written, manually entered counts of the past.

Management gains real-time insights into accurate inventory data from bar code labels. Some users have reporting saving up to 50% in time over physical counts.

Conclusion

Are you using all the bar code label features available in AIM Vision and AutoCOR? Would you like more information about how bar code labels streamline processes? Contact us today.

Want to learn more? Read how a manufacturer achieves ROI with EDI and bar code label applications from AIM Computer Solutions.