Implementation Methodology

AIM’s Proven Implementation Methodology

Implementing a new ERP system can be complex, but with the right approach, it can transform your operations. AIM’s Implementation Methodology ensures a smooth transition by combining a committed team approach with expert project management. This process is designed to keep your project on track, on time, and within budget.

How We Ensure Implementation Success

Our approach is guided by an AIM Project Manager, who will work closely with your team from kick-off to go-live. This collaboration guarantees a seamless migration from your legacy system to your new ERP solution. Here’s how we make it happen:

- Clear Goals and Objectives: We review your project goals to ensure they align with your business needs and the capabilities of the software.

- Custom Implementation Plan: A detailed plan is developed to address the unique requirements of your business.

- Effective Scheduling: We assist in creating and managing schedules to meet key deadlines.

- Comprehensive Training: We coordinate and conduct training sessions to prepare your team.

- Regular Progress Updates: Throughout the process, we provide detailed progress reports to keep everyone informed.

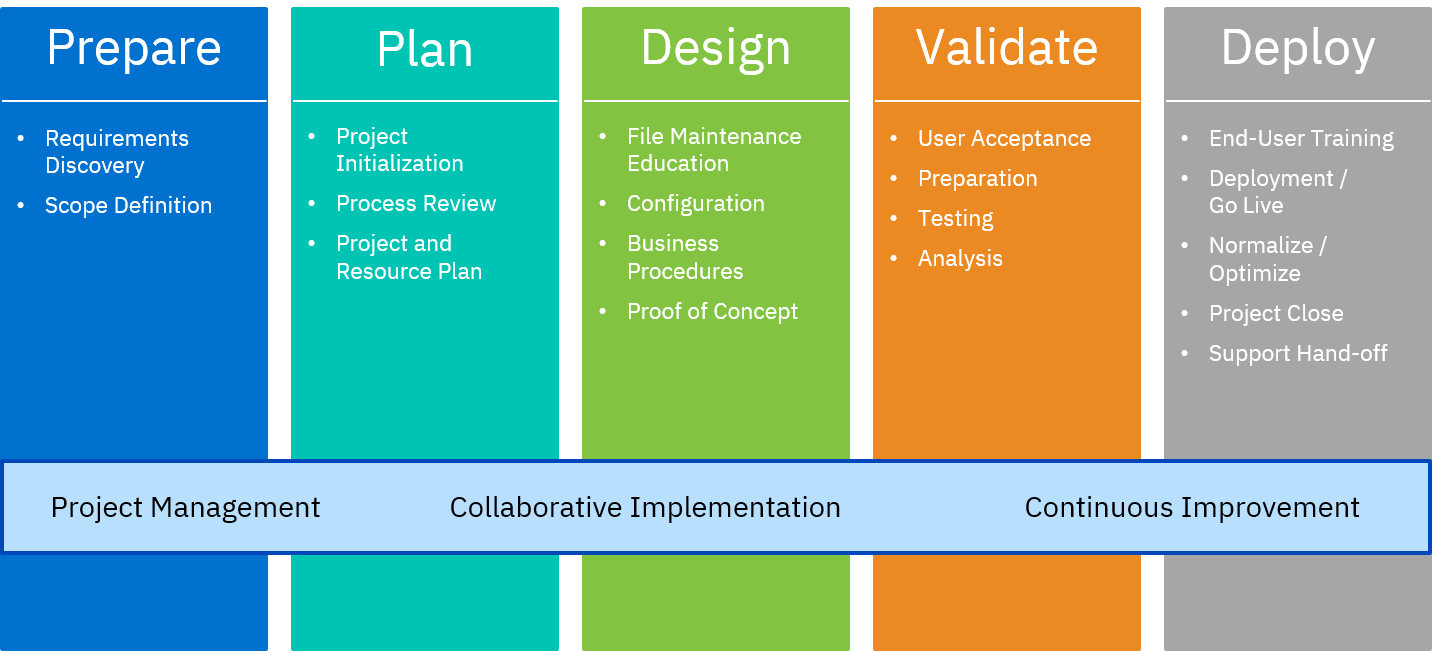

Our Five-Stage Methodology

AIM’s Implementation Methodology follows a structured, five-stage process:

- Prepare: We assess your current system, identify objectives, and establish a clear roadmap for success.

- Plan: A detailed implementation plan is created, tailored to your business and aligned with project goals.

- Design: We configure the ERP system to meet your specific business requirements, ensuring it supports your operations effectively.

- Validate: The system undergoes thorough testing through a Conference Room Pilot to confirm everything is working as expected.

- Deploy: The solution is deployed, and your team transitions to the new system with full support for a successful go-live.

Built-In Checks for Success

At each stage, sign-offs are required to ensure all parties are satisfied before moving forward. This ensures transparency, alignment, and a smooth progression toward the final implementation milestones. The result is an ERP system tailored to elevate your business operations.

Why Choose AIM for Your ERP Implementation?

- Experienced Guidance: Our project managers bring expertise and focus to your implementation.

- Tailored Solutions: Every plan is customized to your specific business needs.

On-Time, On-Budget Delivery: We’re committed to delivering results that meet your expectations without delays.

Explore the AIM Implementation Methodology Chart: