Gain MES Efficiency with AIM Vision Mobility MES App

The AIM Mobility MES application, part of AIM’s suite of manufacturing productivity apps, easily automates production tracking and reporting directly on the shop floor using tablets. The mobility MES app delivers time clock, workcenter load and production statistics including material production counts, downtime reporting, scrap and disposition reporting and printing of shipping or production labels directly from Wi-Fi enables line side printers. By integrating workcenter efficiency and intelligence with the AIM Vision ERP solution, manufacturers gain real time production data and reporting.

How the Mobility MES App Works

The mobility MES app automates three strategic functions on the shop floor that promote efficiency and accuracy in production management: operator time clock, work center data collection, and workcenter load.

Operators easily log in and out on the mobility MES app by employee number or scan using the operator time clock function on the tablet.

The workcenter page serves as the primary data collection function for the mobility MES app. Operators check into the workcenter and read any notes related to the workcenter and its operations, such as notes by: item master, part routing, and part or step. The types of notes are tailored to meet each manufacturer’s specific requirements. Users can decide which operators can add or edit notes. The system allows multiple employees to be logged into each workcenter.

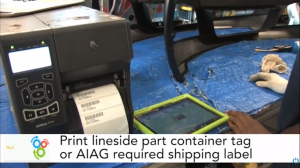

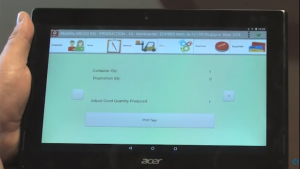

Following log in, the operator moves to the Run screen. When the container at the workcenter is full, the operator prints lineside part container tags or AIAG required shipping labels for each part.

The system increases inventory and back flushes raw materials, keeping an accurate, real-time production count.

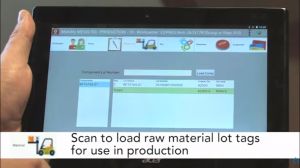

The Materials page shows raw material loaded into the workcenter. The operator scans the lot label as material is delivered and adds it to the material count on the screen.

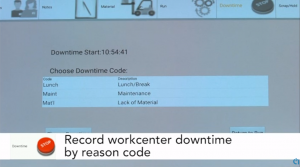

Downtime is a critical production metric. Operators use the Downtime screen on the mobility MES app to report reasons for downtime, such as maintenance, operator break time, or lack of material. When an operator enters downtime, the system clock starts timing the downtime. The operator selects return to run when downtime is over.

Operators track non-conforming parts directly at the workcenter using the Scrap/Hold button by entering reason codes which fit specific requirements. Scrap and hold reason codes might include information such as bubbles, contaminated parts, cracked parts, etc. When the operator enters a part as scrap or on hold, the system indexes the disposition count/quantity on the Run screen. If the operator prints labels at this point, the system back flushes material for good parts and scrap/held parts.

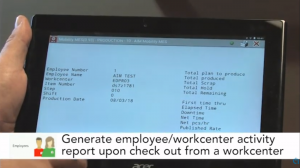

At the end of the shift or before a break, the operator logs out of the workcenter on the mobility MES app. The system confirms the production count by item number and operator at log out. The workcenter operator report shows, for example, total items produced, total scrap or hold, total and net production time, and downtime.

The Workcenter Load function on the mobilty MES app changes the workcenter over from one part number to the next part number. It uses the digital whiteboard feature from the AIM Scheduling function showing workcenters, jobs to be run, jobs loaded into each workcenter, the BOM to make each job, current workcenter status, and the number of pieces scheduled vs. run by workcenter. It also shows if any workcenter is idled by downtime.

Watch the entire video:

Next Steps

If you’re ready to track and report on production efficiencies using the AIM Mobility MES app, let’s talk. It’s time to gain accurate, real-time intelligence on shop floor production.