AIM Vision Rev 11B Service Pack 11 Upgrades Deliver Efficiencies

The experts at AIM Computer Solutions have been busy designing enhanced features for AIM Vision Rev 11B Service Pack 11 to upgrade its EDI, bar code labeling, scheduling, manufacturing, orders, and MES functions.

AIM Vision is a premier ERP solution for automotive suppliers and other manufacturers. It delivers operational efficiency with MRP, CRP, EDI, and MES. The AIM Vision ERP modules and Android-based mobile technology apps streamline and track all front office and shop floor operations.

AIM Vision Rev 11B Service Pack 11 Enhancements

The most recent enhancements in AIM Vision Rev 11B Service Pack 11 relate to applications for:

- EDI

- Bar Code Labeling

- Scheduling

- Manufacturing

- Orders

- AIM Mobility MES

EDI Upgrades

AIM Computer Solutions is known in the global automotive industry for its broad-based EDI software solutions. The AIM Vision Service Pack 11 adds software to process EDI for additional automotive trading partners:

- Iroquois Industries

- Kongsberg Automotive

- L&L Products – Suppliers of Outside Processed Parts (OSP Program)

- Valeo

- Yanfeng Automotive Interiors (YFAI) – Harrison plant

Similarly, with the release of AIM Vision Rev 11B Service Pack 11, AIM Vision offers bar code shipping labels for additional automotive trading partners:

- Douglas Autotech Corporation

- KIA Motors

- Roush Enterprises

- Valeo

- ZF

- Zoox

Scheduling Applications Upgrades

AIM Vision Service Pack 11 adds upgraded features for the Digital Whiteboard, the forecast code table, and the shop calendar.

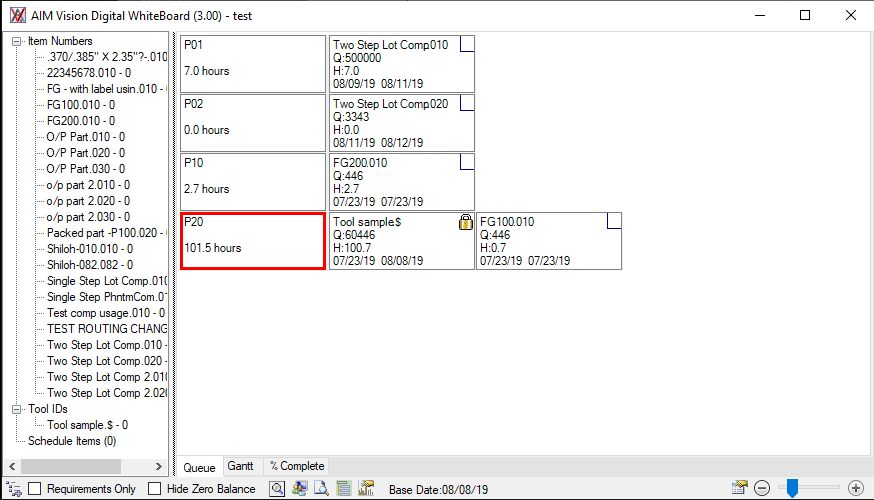

On the Digital Whiteboard, users can now lock all whiteboard scheduled item tiles, hide zero balance tiles, and view Device IDs associated with Item Numbers that are part of a Tooling ID that manufacturers multiple parts per hit. Operators use the Device ID to set up a printer for printing tags for the item from the AIM Mobility MES app.

By locking Digital Whiteboard scheduled item tiles, users can save the balance quantity of each tile as a fixed piece of the production schedule, thereby creating a firm planned order after generating MRP. To implement this feature, check on the new Use Whiteboard for Firm Planned Orders field and specify the Whiteboard Workspace ID that you want to create the Firm Planned Order for when MRP is generated.

Using the Forecast Code Table, operators will now see an indicator to filter Blanket Orders during the Update Demands option based on Blanket Effectivity Date, Blanket Expiration Date, both dates, or with no filtering.

Operators can now modify the shop calendar for multiple workcenters at one time.

Manufacturing Application Upgrades

In the area of production and operations management, AIM Vision service Pack 11 now adds to the Multiple Parts per Tooling ID functions by adding the Device ID per tooling cavity so operators can print lineside labels for tooling that produces multiple parts.

Orders Application Upgrades

Adding features to the orders and supply chain management functions, AIM Vision Service Pack 11 adds a Default Requirement Source field to the Destination Master so users can create a default requirement source on a destination-by-destination basis.

Also included in AIM Vision Service Pack 11 is a Standard Pack Rounding Indicator in the Blanket PO Entry Detail that allows users to specify a default rounding quantity to ship by a value other than rounding to a standard container pack size (for example, by layer or by pallet). New fields in the Container ID table support the necessary calculations of this new function.

AIM Mobility Manufacturing Execution System (MES) App

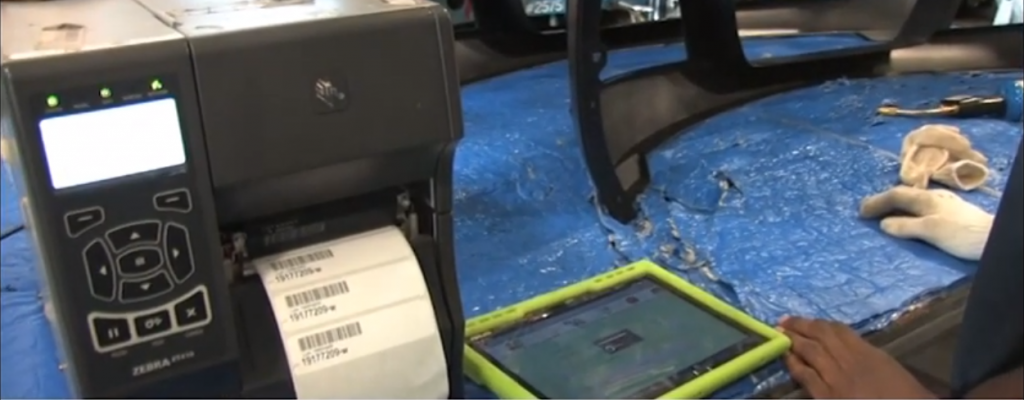

AIM Mobility Apps deliver plant-floor efficiencies with tablet- and scanner-based apps. The AIM Mobility MES app tracks workcenter functionality directly on the plant floor including material production counts, downtime reporting, scrap and disposition reporting, and printing of shipping or production labels directly from Wi-Fi enabled lineside printers.

With AIM Vision Service Pack 11 enhancements, users can now:

- View linked documents for items loaded at the workcenter via a hyperlink from the Workcenter Notes

- Enter scrap/hold quantities more easily on the Workcenter App by utilizing a long press on the quantity field to access a numeric keypad.

- Omit scheduled item tiles on Workcenter Load App with a zero-balance quantity so the workcenter cannot be loaded with an item that does not need to be run.

Training and Customer Support

Contact AIM Computer Solutions to request more information about new features available in AIM Vision. Check out AIM University for classes on specific topics. Customers can access the Service Pack Update via the Support Portal.