AIM Mobility Location Tracking App Delivers Plant Floor Intelligence

Efficiently tracking item locations on the plant floor is critical for streamlined operations. The AIM Mobility Location Tracking App, part of AIM Vision ERP’s suite of manufacturing productivity tools, provides real-time intelligence about the location of inventory and assets. This simple, tablet-based app captures storage locations and associates all items with a virtual location, ensuring you always know where everything is.

Key Features of the AIM Mobility Location Tracking App

The AIM Mobility Location Tracking App answers the question, “Where’s my stuff?” With this app, operators can:

- Create Track IDs or use system-generated lot numbers to assign virtual storage locations.

- Customize tracking data with free-form text that reflects specific plant requirements.

- Conduct daily scans to share updated plant-floor intelligence in real time.

This app is especially valuable for distributors, enabling teams to track and share item locations with accuracy and ease.

How the AIM Mobility Location Tracking App Works

The app includes three primary functions to simplify location tracking:

1. Put to Location

Operators use the Put to Location feature to:

- Enter free-form storage location text.

- Identify items with a track or group ID.

- Create dynamic, customized tracking data that adapts to their specific needs.

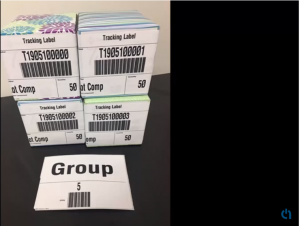

2. Grouping

The Group function allows operators to:

- Combine multiple units and assign them a group ID, much like creating a master shipping label.

- Track grouped units as a single entity for easier storage and retrieval.

3. Location Lookup

Operators can use Location Lookup to:

- Search for items by location ID or item number.

- Query a track ID to find its last recorded location.

- Retrieve a list of all items stored in a specific location.

These features make it simple to manage inventory across complex plant floors or distribution warehouses.

Enhancing Distribution Efficiency

In a warehouse setting, the AIM Mobility Location Tracking App excels at providing real-time insights. With a single scan, operators can update the entire team about product locations, ensuring everyone stays informed. When paired with the AIM Mobility Shipping App, operators can dynamically locate lot numbers in FIFO (First-In, First-Out) order. This integration helps improve inventory accuracy and ensures timely shipments.

Operators enter free-form storage location text and identify the track or group ID by location for each item using the Put to Location function.

Advanced Features for Location Tracking

The app includes several advanced capabilities to further streamline operations:

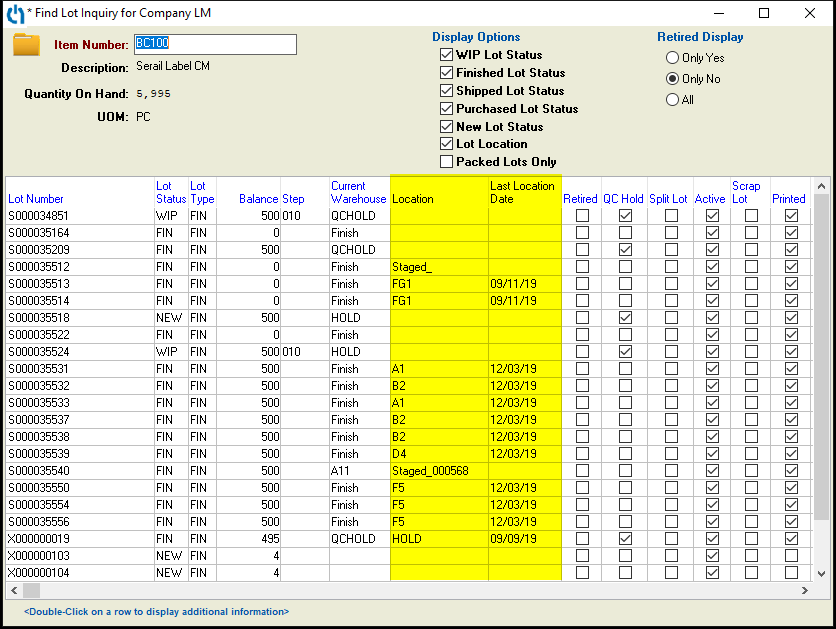

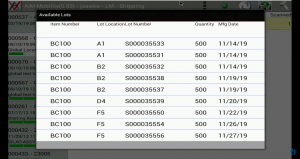

- Lot Inquiry Screen: Displays item locations and the last location date. It provides information for all containers of a specific item, sorted in FIFO order, with recorded location data.

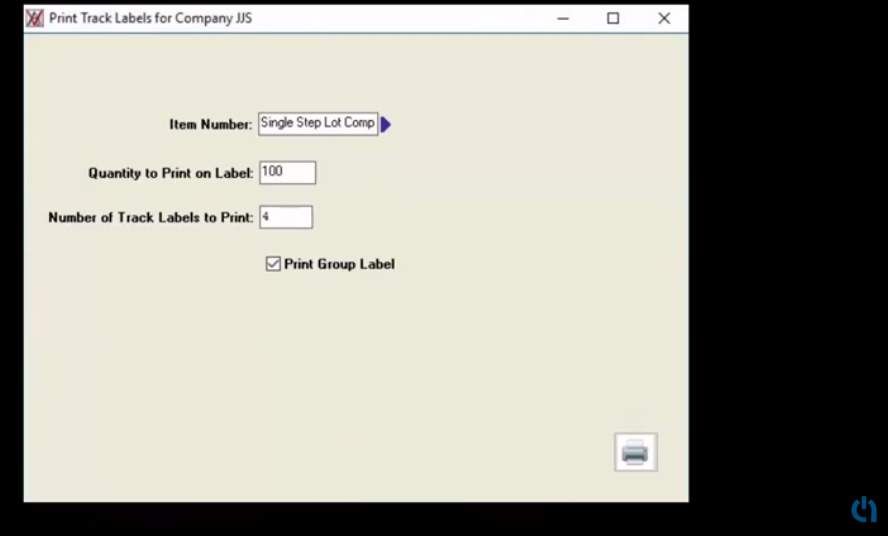

- Print Track Labels: Links item numbers with tracking IDs, creating a seamless tracking system.

- Group Label Printing: Prints sequentially numbered group tags, either on demand or in advance for quick use.

- Reprint Labels: Easily reprint damaged or lost labels to maintain accurate tracking.

These features ensure that operators can efficiently track, locate, and manage inventory on the plant floor.

Why Choose the AIM Mobility Location Tracking App?

This tablet app delivers:

- Real-Time Intelligence: Gain immediate visibility into item locations and share updates across teams.

- Improved Accuracy: Reduce errors by dynamically tracking and grouping items.

- Customizable Tracking: Tailor tracking data to meet the unique needs of your plant or warehouse.

Watch the entire AIM Mobility Location Tracking app video.

Take the Next Step

Are you ready to improve location tracking and gain real-time plant-floor intelligence? The AIM Mobility Location Tracking App is the solution you need for efficient and accurate inventory management. Contact us today to learn more or schedule a demo. It’s time to streamline your operations with AIM Vision ERP.