EDI Standards: What They Are and Why They Matter

Electronic Data Interchange (EDI) standards are the foundation that make automated, system-to-system business communication possible. For automotive suppliers, EDI standards are the backbone of compliant order management, shipping accuracy, and supplier scorecard performance. Without clearly defined EDI standards and EDI specifications, companies would struggle to exchange purchase orders, shipping notices, invoices, and forecasts accurately—especially across complex supply chains.

For automotive suppliers and manufacturers in particular, electronic data interchange standards are not optional. OEMs and Tier customers mandate specific EDI formats, transaction sets, and compliance rules that directly impact shipping accuracy, ASN acceptance, supplier scorecards, and audit readiness under frameworks like MMOG/LE and IATF 16949.

Yet, many organizations still ask the same questions:

- What are EDI standards, really?

- How are EDI standards different from EDI specifications?

- Which standards matter most for my industry and trading partners?

In this guide, we’ll break down EDI standards and specifications in plain terms, explain how they work together, and show why choosing—and managing—the right EDI approach is critical for operational efficiency, compliance, and long-term scalability.

If you’re looking to reduce EDI errors, avoid chargebacks, and stay compliant with customer mandates, understanding EDI standards is the first step.

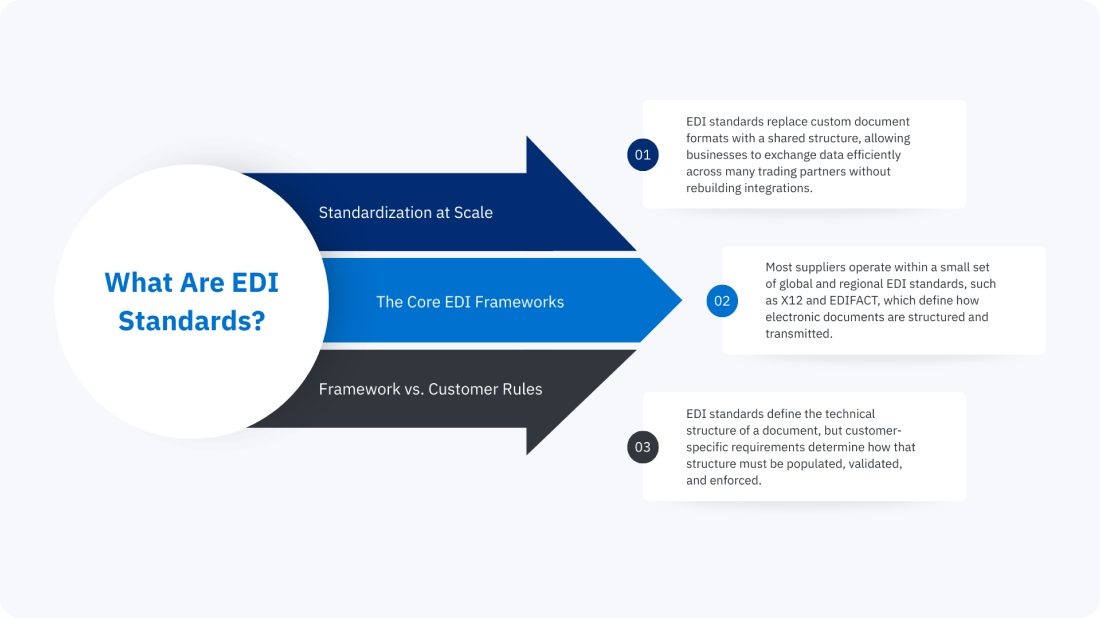

What Are EDI Standards?

EDI standards are agreed-upon rules that define how electronic business documents are structured, formatted, and transmitted between trading partners. They ensure that when one system sends data, the receiving system understands it exactly as intended—without manual interpretation or rework.

Understanding EDI standards helps suppliers move from reactive issue‑resolution to predictable, rules‑based execution across ERP, shipping, and labeling systems.

At a high level, EDI standards specify:

- The structure of a document (segments, loops, and elements)

- The order and format of data fields

- The rules for validation and compliance

- The syntax used to transmit information electronically

Think of EDI standards as a shared language. When both sender and receiver follow the same standard, data flows automatically and accurately between ERP systems, WMS platforms, and other business applications.

Why EDI Standards Exist

Before EDI standards, companies exchanged business documents using proprietary formats. Every new customer or supplier required custom integrations, increasing costs and errors. EDI standards solved this by creating a common framework that allows businesses to scale electronic communication across hundreds—or thousands—of trading partners.

For automotive suppliers, this standardization is critical. OEMs and Tier customers rely on EDI standards to:

- Transmit releases and forecasts (e.g., 830, 862)

- Authorize shipments and sequencing

- Validate ASNs (856) before freight arrives

- Maintain accurate cumulative (CUM) accounting

- Support audit and compliance requirements

These requirements are not theoretical—they directly affect daily shipping decisions, ASN acceptance rates, and audit outcomes for automotive suppliers.

Common EDI Standards Used in Automotive Supply Chains

While there are many EDI standards worldwide, most manufacturers work with a small set depending on geography and industry:

- ANSI ASC X12 – The dominant EDI standard in North America

- UN/EDIFACT – Widely used internationally

- Industry-specific subsets – Such as automotive standards (e.g., ODETTE, VDA) or healthcare (HIPAA)

Each standard defines how documents are structured—but not the business rules themselves. That’s where EDI specifications come into play, which we’ll cover next.

EDI Standards vs. Business Requirements

An important distinction:

EDI standards define the technical framework, but they don’t define customer-specific requirements.

For example:

- Two OEMs may both use X12

- Both may send an 856 ASN

- Each may require different fields, labels, or validation logic

This is why understanding EDI standards alone isn’t enough—automotive suppliers must also manage constantly changing specifications without disrupting production or shipping. Successful EDI programs must also manage EDI specifications, customer mandates, and ongoing changes—without disrupting operations.

In the next section, we’ll break down EDI specifications, explain how they differ from standards, and show why they are often the real source of EDI complexity for suppliers.

What Are EDI Specifications (and How They Differ From EDI Standards)?

While EDI standards define the overall structure and syntax for electronic documents, EDI specifications define the exact rules for how those standards must be used by a specific customer, industry, or trading partner.

This distinction is critical—and often misunderstood.

If EDI standards are the language, EDI specifications are the rulebook that tells you:

- Which documents are required

- Which data elements are mandatory vs optional

- How fields must be populated

- What values are allowed

- How documents are validated before acceptance

EDI Standards vs. EDI Specifications: A Simple Comparison

| EDI Standards | EDI Specifications |

|---|---|

| Define document structure and syntax | Define how the document must be used |

| Industry-wide (e.g., X12, EDIFACT) | Trading partner–specific |

| Technically flexible | Strict and enforced |

| Rarely change | Frequently updated |

For example, the X12 standard defines what an 856 Advance Ship Notice (ASN) looks like.

An OEM’s EDI specification defines:

- Which segments must be present

- Which reference numbers are required

- How container IDs, serial numbers, or dock codes must be formatted

- What causes the ASN to be accepted or rejected

Why EDI Specifications Cause Most EDI Problems

Many suppliers assume that once they “support X12” or “support EDIFACT,” they are EDI-ready. In reality, most EDI failures happen at the specification level, not the standard level.

Common issues include:

- Missing required segments or qualifiers

- Incorrect codes or formats

- Customer-specific validation rules not met

- Changes to specifications not implemented in time

In automotive supply chains, these issues lead directly to:

- ASN rejections

- Shipment delays

- Chargebacks

- Supplier scorecard penalties

Examples of EDI Specifications in Practice

A single supplier may receive:

- An 830 Material Release from multiple OEMs

- All using the same EDI standard

- Each with different rules for CUMs, dates, forecast buckets, and references

Even within the same document type:

- One customer may require cumulative quantities

- Another may prohibit them

- One may enforce strict date logic

- Another may allow flexibility

These differences are not controlled by the EDI standard—they are controlled by EDI specifications.

How EDI Specifications Are Managed

EDI specifications are typically published by:

- OEMs

- Tier 1 customers

- Industry groups (e.g., AIAG subsets)

They are updated regularly as business rules evolve. Successful suppliers must:

- Monitor changes

- Test updates

- Ensure ERP and labeling systems remain compliant

- Validate outbound documents before transmission

This is why modern EDI solutions focus less on “mapping” and more on embedded business logic and validation that adapts to specification changes without disrupting operations.

In the next section, we’ll look at the most common EDI standards used today, including X12 and EDIFACT, and explain where each is typically used across industries and regions.

The Most Common EDI Standards Used Today

Although there are many electronic data interchange standards worldwide, most manufacturers and suppliers encounter a small group of widely adopted formats. Which EDI standard you use is typically driven by geography, industry, and customer mandates rather than personal preference.

Understanding where each standard is used—and why—helps suppliers anticipate requirements and avoid surprises during onboarding or audits.

ANSI ASC X12

ANSI ASC X12 is the most widely used EDI standard in North America. It defines the structure for hundreds of transaction sets covering purchasing, logistics, finance, and forecasting.

In manufacturing and automotive supply chains, X12 is commonly used for documents such as purchase orders, material releases, shipping schedules, and advance ship notices. While the standard itself is flexible, OEMs and Tier customers enforce strict specifications on top of it, which is why simply “supporting X12” is rarely sufficient for compliance.

X12 remains dominant because of its long history, broad ERP support, and deep adoption across U.S.-based trading partners.

UN/EDIFACT

UN/EDIFACT is the international counterpart to X12 and is widely used across Europe, Asia, and other global markets. Structurally similar in purpose but different in syntax, EDIFACT is commonly required by multinational OEMs and global Tier 1 suppliers.

In automotive environments, EDIFACT is often paired with Just-in-Time (JIT) and sequencing processes, where timing, quantities, and references must be precisely aligned. For suppliers supporting both North American and global customers, managing X12 and EDIFACT simultaneously is a common challenge.

Industry and Regional Subsets

Some industries and regions use subset standards, which are specialized implementations built on top of broader EDI standards. These subsets narrow the allowed options and define industry-specific rules to reduce ambiguity.

In automotive supply chains, standards such as ODETTE and VDA are examples of regionally driven approaches that align closely with European OEM requirements. While they still follow core EDI principles, they introduce additional conventions that suppliers must support to remain compliant.

XML and Modern EDI Formats

In addition to traditional EDI standards, some organizations use XML-based formats or API-driven integrations. These are often positioned as “modern EDI,” but in reality, they coexist with—not replace—traditional EDI in most manufacturing environments.

OEMs and large trading partners continue to rely heavily on established EDI standards because of their reliability, auditability, and deep integration into ERP and compliance processes.

Why Multiple EDI Standards Matter

It’s common for a single supplier to support:

- X12 for one customer

- EDIFACT for another

- Industry-specific subsets for others

Each standard brings its own syntax rules, validation requirements, and implementation nuances. The real complexity comes not from the number of standards, but from managing them consistently alongside customer-specific EDI specifications.

In the next section, we’ll take a closer look at EDI transaction types and document structures, explaining how standards and specifications come together in real-world documents like purchase orders, releases, and ASNs.

EDI Transaction Types and Document Structure

EDI standards and specifications come together in the form of EDI transaction types—the actual business documents exchanged between trading partners. These transactions represent familiar processes like ordering, shipping, invoicing, and forecasting, but in a structured electronic format that systems can process automatically.

Each transaction type serves a specific business purpose and follows a defined structure dictated by the EDI standard, then tightened by customer-specific EDI specifications.

What Is an EDI Transaction Set?

An EDI transaction set is a standardized electronic document designed to replace paper-based processes. Instead of emails, PDFs, or spreadsheets, structured EDI messages flow directly between systems, eliminating manual data entry and reducing errors.

For example, a purchase order sent via EDI contains the same information as a paper PO—but it’s formatted so an ERP system can immediately interpret and act on it.

Each transaction set is identified by a numeric or alphanumeric code, depending on the EDI standard being used.

Common EDI Transaction Types

In manufacturing and automotive supply chains, certain transaction types appear repeatedly throughout the order-to-cash cycle.

A purchase order (such as the X12 850) authorizes a supplier to produce or ship goods. Material releases and shipping schedules communicate forecasted and firm demand, often replacing traditional blanket orders. Advance ship notices (ASNs) confirm exactly what is being shipped, how it is packaged, and when it will arrive. Invoices transmit billing details, while acknowledgments confirm whether documents were received and accepted.

Although these documents may sound straightforward, each one can include hundreds of data elements—and each element may be required, optional, or conditional based on the customer’s specification.

How EDI Documents Are Structured

Regardless of the transaction type, EDI documents follow a consistent structural hierarchy.

At the top level is the transaction set itself. Within it are segments, which group related information together, such as dates, addresses, quantities, or references. Each segment contains data elements, which hold the actual values—part numbers, quantities, dates, container IDs, and more.

EDI standards define which segments exist and the order they appear in. EDI specifications determine which segments must be used, which values are allowed, and how strict validation will be.

This layered structure is what allows EDI to be both flexible and enforceable at the same time.

Why Structure Matters in the Real World

Because EDI documents are machine-read, structure is non-negotiable. A missing segment, an invalid qualifier, or an unexpected value can cause a document to be rejected—even if the shipment itself is correct.

In automotive environments, this often means:

- An ASN rejected before the truck arrives

- A shipment held at the dock

- Delayed receipts and payment

- Chargebacks tied to documentation errors, not physical issues

Understanding transaction structure helps suppliers see why EDI compliance is not just an IT concern, but a core operational requirement.

From Transactions to Business Execution

EDI transactions don’t exist in isolation. They drive production schedules, shipping execution, labeling, cumulative accounting, and financial reconciliation inside ERP systems. When EDI transactions are accurate and aligned with customer specifications, operations run smoothly. When they’re not, problems cascade quickly across departments.

In the next section, we’ll explore how EDI standards and transactions integrate with ERP systems, and why ERP alignment is essential for maintaining accuracy, compliance, and scalability.

How EDI Standards Integrate With ERP Systems

EDI standards only deliver value when they are tightly integrated with an organization’s ERP system. This integration is where many automotive suppliers struggle—and where the right EDI architecture makes a measurable difference. Without that connection, EDI becomes little more than an electronic inbox—detached from production planning, shipping execution, inventory, and financials.

In a properly integrated environment, EDI standards act as the communication layer, while the ERP system acts as the system of record that turns EDI data into real operational actions.

From EDI Message to ERP Action

When an EDI document is received, it must be translated from its standardized format into data the ERP system understands. A material release updates demand and scheduling. A shipping schedule authorizes what can ship and when. An ASN confirms what left the dock and adjusts inventory and cumulative quantities. An invoice triggers financial posting and reconciliation.

EDI standards define how the data is structured. ERP integration determines what happens next.

If this handoff is weak or manual, suppliers experience delays, errors, and rework. If it is automated and rules-based, EDI becomes a force multiplier for efficiency.

Why ERP Alignment Is Critical

ERP systems are built to manage orders, inventory, production, and finance—not to interpret raw EDI syntax. That interpretation must happen in a controlled layer that understands both EDI standards and ERP business logic.

When EDI and ERP are not aligned, common problems appear quickly:

- Orders that don’t match production schedules

- Shipments created outside of authorized releases

- Inventory discrepancies after shipping

- CUM mismatches between supplier and customer

- Invoices that don’t reconcile to shipments

These issues are rarely caused by the EDI standard itself. They are caused by poor integration between EDI transactions and ERP processes.

The Role of EDI Specifications in ERP Integration

Customer-specific EDI specifications often determine how ERP data must be populated. One customer may require cumulative quantities to be calculated a certain way. Another may require ship dates to account for transit time. Another may enforce strict container-level detail in ASNs.

If ERP integration does not account for these specification-level rules, suppliers are forced into manual adjustments—spreadsheets, overrides, and exception handling that increase risk and labor.

Modern EDI-integrated ERP environments embed these rules directly into processing logic, ensuring that what ships, labels, and invoices all align with customer expectations automatically.

Scalability and Change Management

As suppliers add customers, plants, or programs, the relationship between EDI standards and ERP becomes even more important. Each new trading partner introduces new specifications, validation rules, and document flows.

Without a scalable integration approach, changes require custom development, re-mapping, and retesting—often under tight timelines. With the right integration model, changes can be absorbed without disrupting core ERP operations.

This is especially important in industries like automotive, where customer mandates evolve continuously and compliance is measured daily.

EDI as an Operational System, Not Just IT Infrastructure

The most successful suppliers treat EDI as part of their operational backbone, not as a background IT function. When EDI standards and ERP systems work together seamlessly, organizations gain better visibility, stronger compliance, and more predictable execution across the entire order-to-ship cycle.

In the next section, we’ll look at the business benefits of standardized EDI, including accuracy, speed, compliance, and cost reduction—and why EDI standards remain essential even as technology evolves.

The Business Benefits of Using Standardized EDI Standards

EDI standards are often discussed in technical terms, but their real value is operational. When standardized EDI is implemented correctly, it becomes a competitive advantage—not just a compliance requirement.

At its core, standardized EDI enables companies to exchange high-volume, time-sensitive data with speed and precision. Instead of reacting to problems after they occur, suppliers can operate with greater predictability and control across ordering, shipping, and billing processes.

Improved Accuracy and Fewer Errors

One of the most immediate benefits of standardized EDI is accuracy. Because data is exchanged system-to-system using defined structures and validation rules, the risk of human error is dramatically reduced. Quantities, dates, part numbers, and references are captured once and reused consistently across processes.

In industries like automotive, this accuracy directly affects ASN acceptance, cumulative accounting, and supplier scorecards. Errors that once appeared at the dock or during invoicing are often prevented before a document is even transmitted.

Faster Processing and Shorter Cycle Times

Standardized EDI removes manual handoffs that slow down operations. Orders flow directly into ERP systems, shipping schedules update production plans automatically, and ASNs are generated from actual shipment data rather than rekeyed after the fact.

This speed matters. Faster data flow means quicker response to demand changes, fewer last-minute expedites, and tighter alignment between planning and execution.

Stronger Compliance and Audit Readiness

Many suppliers first adopt EDI to meet customer mandates, but standardized EDI makes ongoing compliance far easier to maintain. When EDI standards and specifications are enforced consistently, documentation aligns naturally with OEM and Tier requirements.

This is especially important for suppliers operating under MMOG/LE and IATF 16949 expectations, where traceability, consistency, and documented processes are critical. These frameworks assume consistent, standards‑based electronic communication—making EDI standards foundational to audit readiness.

Standardized EDI creates a reliable digital audit trail that supports both customer reviews and internal quality initiatives.

Lower Operational Costs Over Time

While EDI requires upfront investment, standardized implementations reduce long-term costs. Manual data entry, spreadsheet reconciliation, and exception firefighting consume significant labor. Standardized EDI minimizes these activities by preventing issues rather than correcting them later.

As trading partner volume grows, standardized EDI also scales more efficiently than custom integrations. Adding customers becomes a controlled process instead of a disruptive one.

Better Visibility Across the Supply Chain

When EDI transactions are consistent and integrated with ERP systems, visibility improves across departments. Operations teams can see what is authorized to ship. Shipping teams know exactly how products must be packaged and labeled. Finance teams can reconcile shipments and invoices with confidence.

This shared visibility reduces internal friction and helps organizations respond more quickly to changes—whether those changes come from customers, suppliers, or market conditions.

Standardized EDI is not just about sending data electronically. It is about creating a stable, repeatable foundation for executing complex supply chain processes with confidence.

In the next section, we’ll look at common challenges suppliers face with EDI standards and specifications, and why many issues persist even after EDI is implemented.

Common Challenges With EDI Standards and Specifications

Despite the maturity of EDI standards, many suppliers continue to struggle with EDI on a day-to-day basis. The issue is rarely the standard itself. Instead, problems arise from how standards, specifications, and operational processes intersect in real environments. Managing EDI standards successfully is less about supporting more formats and more about building disciplined, scalable processes around them.

Understanding these challenges helps explain why EDI initiatives that look “complete” on paper still create friction on the shop floor and shipping dock.

Customer-Specific Variations Multiply Complexity

Even when customers use the same EDI standard, their specifications can differ significantly. One customer may require cumulative quantities in every release, while another forbids them. One may enforce container-level detail in ASNs, while another focuses on pallet-level data. These variations force suppliers to manage multiple rule sets simultaneously.

Over time, this complexity compounds. As more customers are added, EDI logic becomes harder to maintain, especially when specifications change without much notice.

Specification Changes Are Constant

EDI specifications are living documents. OEMs and Tier customers update requirements in response to new programs, regulatory changes, or internal process improvements. These updates may affect required segments, validation rules, labeling data, or timing expectations.

Suppliers that rely on static mappings or manual workarounds often discover these changes only after documents are rejected. By then, shipments may already be delayed and internal teams are scrambling to respond.

Poor Visibility Into EDI Exceptions

Another common challenge is visibility. When EDI transactions fail, the root cause is not always obvious. A rejected ASN may be caused by a missing qualifier, an invalid date, or a mismatch between shipped quantities and authorized releases.

Without clear exception reporting and validation feedback, teams spend hours troubleshooting issues that could have been identified earlier in the process. This lack of visibility turns EDI into a reactive exercise instead of a controlled workflow.

Misalignment Between EDI and Operations

EDI failures often expose gaps between electronic data and physical execution. A shipment may be packed correctly, but labeled incorrectly. Inventory may be accurate, but cumulative quantities may not reconcile. Production may meet demand, but shipping may violate authorization rules.

These problems occur when EDI is treated as a standalone technical function instead of being aligned with production, shipping, and inventory processes. When EDI and operations are disconnected, errors surface at the worst possible moment—when goods are already in transit.

Overreliance on Manual Intervention

Many suppliers compensate for EDI complexity with manual steps: spreadsheets to reconcile CUMs, hand checks of labels, last-minute ASN edits, or offline communication with customers. While these workarounds may keep shipments moving in the short term, they introduce risk and are difficult to scale.

Manual processes also make it harder to meet compliance expectations, where consistency and traceability are critical.

These challenges explain why EDI problems persist even in organizations that have used EDI for years. The solution is not abandoning standards—it is managing them more intelligently.

In the next section, we’ll explore best practices for managing EDI standards and specifications, and how suppliers can reduce risk while improving accuracy and control.

Best Practices for Managing EDI Standards and Specifications

Managing EDI successfully is less about supporting a long list of standards and more about how those standards and specifications are operationalized. Suppliers that struggle with EDI usually have the same issue: their processes can’t keep up with change, scale, or complexity.

The following best practices help organizations move from reactive EDI firefighting to controlled, predictable execution.

Treat EDI as an Operational Process, Not Just IT

EDI touches planning, production, shipping, quality, and finance. When it lives only in IT, problems surface late—often after a shipment is already built or on the truck. Strong EDI programs align standards and specifications directly with operational workflows so issues are identified before they become costly.

This means validating demand before it hits the production schedule and validating shipments before labels are printed or ASNs are sent.

Centralize EDI Rules and Business Logic

One of the most effective ways to manage complexity is to centralize EDI rules instead of scattering them across maps, scripts, and manual procedures. Customer-specific requirements should be embedded into repeatable logic that applies consistently every time a document is processed.

When rules are centralized, changes are easier to manage and less likely to break downstream processes.

Validate Early, Not After the Fact

Best-in-class EDI environments validate documents before they are transmitted. Instead of discovering problems through rejected ASNs or 824 messages, suppliers can catch missing data, invalid formats, or authorization issues during shipment preparation.

Early validation shifts EDI from a corrective process to a preventive one, reducing rework and stress across teams.

Maintain Strong Change Management Discipline

Because EDI specifications change frequently, suppliers need a disciplined approach to updates. This includes monitoring customer communications, testing changes in advance, and ensuring all affected departments understand what is changing and why.

Organizations that treat EDI updates as controlled events—rather than emergencies—maintain higher compliance and fewer disruptions.

Design for Scalability

EDI programs should be built with growth in mind. New customers, new plants, and new programs should not require starting from scratch. Scalable EDI architectures allow suppliers to absorb additional standards and specifications without increasing manual effort or risk.

This is especially important for automotive suppliers supporting multiple OEMs, Tier customers, and regional requirements.

Align Physical Execution With Electronic Data

Finally, EDI only works when physical execution matches electronic intent. Shipping processes, labeling, containerization, and scanning must all reflect what is being transmitted electronically. When these stay in sync, ASNs are accepted, inventory stays accurate, and customer confidence improves.

The Future of EDI Standards

EDI has been around for decades, and despite frequent predictions of its decline, it remains the backbone of high-volume, mission-critical supply chains. What is changing is how EDI standards are implemented, managed, and integrated into modern systems.

The future of EDI is not about replacing standards like X12 or EDIFACT—it’s about making them easier to manage, more resilient to change, and more tightly connected to real-time operations.

EDI Isn’t Going Away—It’s Evolving

OEMs and large Tier customers continue to rely on traditional EDI standards because they are proven, auditable, and deeply embedded in ERP and compliance processes. For industries like automotive, EDI remains the safest and most reliable way to enforce consistent communication across thousands of suppliers.

What is evolving is the infrastructure around EDI. Cloud platforms, improved validation engines, and smarter integration layers are reducing the friction that historically made EDI difficult to manage.

Cloud-Based EDI and Centralized Control

More suppliers are moving away from plant-by-plant or map-by-map EDI management toward centralized, cloud-enabled architectures. This approach makes it easier to deploy updates, monitor transactions, and enforce consistent business rules across multiple locations.

Centralization also improves visibility. Instead of discovering problems through rejected documents, teams can see potential issues as they develop and address them proactively.

APIs and “Modern EDI”

APIs, XML, and JSON-based integrations are increasingly used alongside traditional EDI, particularly for analytics, portals, and lightweight data exchanges. In some cases, APIs simplify connectivity for smaller partners or internal systems.

However, in regulated and high-volume environments, APIs complement EDI rather than replace it. Traditional EDI standards still provide the structure, discipline, and validation rigor that OEMs depend on for execution and compliance.

Automation and Embedded Business Logic

The most meaningful advances in EDI are happening at the business-logic level. Instead of relying on static mappings, modern EDI solutions embed customer-specific rules directly into processing workflows. This allows systems to adapt automatically as specifications change, without constant rework.

Automation is also improving how EDI aligns with physical execution. Real-time scanning, validation, and confirmation processes ensure that what ships, what is labeled, and what is transmitted electronically stay in sync.

What This Means for Suppliers

As EDI continues to evolve, the suppliers that succeed will be those that treat EDI standards as a strategic capability rather than a necessary evil. The focus will shift away from “supporting formats” and toward managing change, enforcing compliance, and enabling scalability.

EDI standards will remain the foundation—but smarter tools and better integration will define how effectively they are used.

Key Takeaways: Making EDI Standards Work for Your Business

EDI standards are not just a technical requirement—they are the foundation that enables reliable, scalable, and compliant supply chain execution. Standards like X12 and EDIFACT provide the common structure that allows systems to communicate, but it is EDI specifications that determine whether those communications actually succeed in the real world.

For most suppliers, EDI challenges do not come from a lack of standards support. They come from managing constant specification changes, aligning EDI with ERP and shipping processes, and maintaining accuracy under pressure. When EDI is treated as a standalone IT function, issues surface late and costs rise. When it is treated as an operational system, EDI becomes a source of stability and control.

The most effective EDI environments share a few traits. They validate data early, embed customer-specific business rules into repeatable logic, and keep physical execution aligned with electronic intent. They are designed to scale as customers, plants, and programs are added—without relying on manual workarounds or fragile customizations.

As EDI continues to evolve, the standards themselves are not disappearing. Instead, the way companies implement and manage them is improving. Cloud platforms, automation, and tighter ERP integration are reducing friction while preserving the discipline and reliability that EDI standards were designed to deliver.

For organizations looking to reduce errors, improve compliance, and future-proof their operations, the priority is clear: understand the difference between EDI standards and EDI specifications, and build processes that manage both with precision.

When EDI standards are implemented thoughtfully, they stop being a burden—and start becoming a competitive advantage.

Ready to Simplify EDI Standards and Stay Compliant?

Managing EDI standards and specifications doesn’t have to mean constant firefighting, rejected ASNs, or last‑minute fixes. With the right approach, automotive suppliers can embed compliance directly into order management, labeling, and shipping workflows—reducing risk while improving execution.

Let’s talk about how AIM helps automotive suppliers turn EDI standards into a competitive advantage.