EDI Software for Automotive Suppliers

Electronic Data Interchange (EDI) is the exchange of business documents between business partners. Businesses long ago discovered the many benefits of going digital that include:

- increasing processing speed of getting orders into the system

- reducing input errors from paper-based entry

- improving business efficiency through automatic exchange of information across the supply chain that can be tracked in real-time

- reducing inventory levels due to shortened order processing and delivery times

- facilitating the on-boarding of new and or global partners through a common business language

- adopting a demand-driven business model rather than a supply one

- promoting corporate social responsibility and sustainability through paperless exchange of information

Automotive EDI Standards

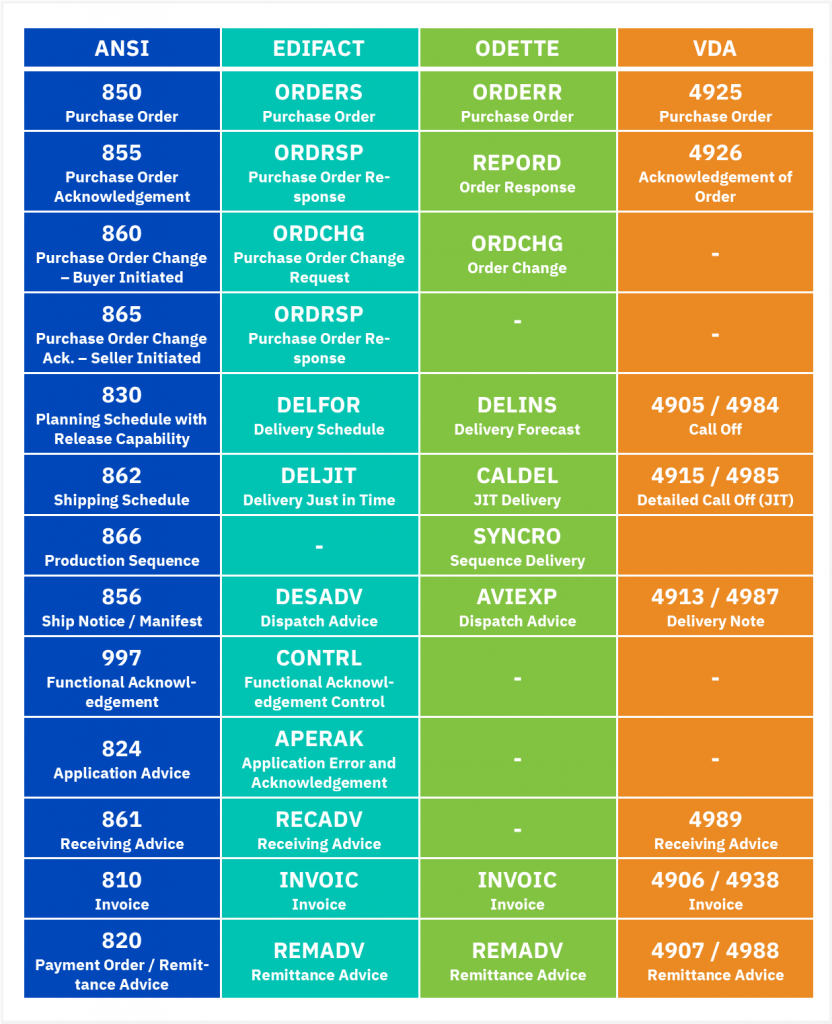

The interchange of data from IT system to IT system, rather than from paper via human intervention, requires a standard format be defined and followed. Common standards used in the automotive industry include ANSI ASC X12, UN/EDIFACT, ODETTE and VDA.

In automotive manufacturing, automotive OEMs (original equipment manufacturers) mandate to their suppliers what standard and version of EDI must be followed in the trading partner relationship. Similarly, Tier 1s and Tier 2s who are large enough to have their own EDI information technology departments will also mandate to their suppliers what EDI standard and versions must be followed in the trading partner relationship. Customers and suppliers with a mutually agreed upon standard and version will be able to communicate electronically regardless of where they fall in the supply chain.

Automotive EDI Transactions

While there are dozens of different types of electronic documents to exchange, the most common in the automotive industry include:

- ordering transactions such as purchase orders, purchase order acknowledgements, purchase order changes (buyer initiated) and purchase order change acknowledgements (seller initiated)

- material management transactions such as planning schedules (forecasts), shipping schedules, production sequence delivery schedules, Kanban delivery requirements, and ASNs (advance ship notices / manifest)

- financial transactions such as invoices and remittance advice (electronic funds transfer notification)

The following chart is a cross reference of common automotive EDI transactions across the four EDI standards.

Automotive EDI Processing

Depending on the OEM (customer), a typical EDI communication begins with a purchase order (850/ORDERS) or the planning schedule / forecast (830/DELFOR) message. This document communicates the weekly demand for a specific part to the supplier. These weekly requirements can be identified as firm quantities or planning quantities. The further in the future the requirement week, the more likely it is a planning quantity. The forecast provides the supplier with quantities that can be used to calculate their future material demands.

Frequently customers also send shipping schedule (862/DELJIT) messages with daily ship quantities needed for just-in-time consumption at the customer. This document also contains specific details related to unloading points (line feed location and dock code), and special shipping data needed on ASNs and product package bar code labels (RAN #, Manifest, Kanban number).

Some OEMs also send production sequence schedules (866) to allow the customer to identify the exact sequential order the parts should arrive in at the location. These are used when the goods will be unloaded from a conveyance method in the order they will be used. This is typical when the supplier provides products used in the final stages of manufacturing on the assembly line at the OEM, and need to be loaded at the supplier in paint color order.

As products leave the supplier dock, ASN (856/DESADV) messages must be transmitted to the customer to advise them that the product has been dispatched from the supplier. ASNs contain packaging information including pallet details, number of container packages and serial numbers associated with the containers (boxes) and pallets.

Functional acknowledgement (997/CONTRL) messages are a simple electronic signal to advise the supplier of the receipt of the ASN by the customer. If the ASNs was processed into the customer’s IT system, the acknowledgement is positive.

When product arrives at the OEM (customer), the customer may scan the master labels, mixed load labels and serial labels on the shipment and compare it with the data provided on the ASN. The OEM may use a receiving advice (824/RECADV) message to communicate back to the supplier information related to the quantities received and if there were any deviations in the numbers sent on the ASN versus received.

Payment details are communicated by sending an electronic invoice (810/INVOIC) message, and sometimes used in addition to payment order or remittance advice (820/REMADV) messages used in to advice of an electronic funds transfer (EFT).

Managing EDI for Many Customers

These days, every business partnership you enter into will come with their own set of EDI mandates and requirements. In order to succeed, it is essential that you have an EDI solution that can handle the various EDI formats and versions, and transaction sets needed to meet these mandates. In addition, it is imperative that managing these various EDI requirements is not a challenge to getting new business. Suppliers need to be able to focus on what they are good at – making high quality parts for the automotive industry, and not have to worry about becoming an EDI expert.

That’s where AIM Computer Solutions’ comes in. We’ve been focused on automotive EDI since the early days of the Automotive Industry Action Group (AIAG). In its introductory years, we actively participated and throughout the last three and a half decades we have continued to support and participate in the AIAG.

As a strong partner in EDI solutions, AIM has integrated AIAG, UN/EDIFACT, ODETTE and VDA EDI specifications in the core of its business solution software offering. Regardless of the EDI Standard, AIM maps all inbound EDI information into a common format so orders can be created with an ERP solution. This, in turn, means companies do not need an EDI expert on hand to interpret the data.

Today’s automotive customers send a multitude of unique data on the inbound EDI transmissions. Suppliers are expected to utilize this information on container and pallet bar code labels, as well as include this information on shipping paperwork and return it on the ASN. AIM Order Management stores this special reference information for use in the AIM Shipping and Bar Code applications. The outbound EDI transmission then includes this on the ASN, as mandated by the OEM / customer.

Industry best practices in the automotive supply chain include not only EDI communications with your customers, but also with your suppliers. This means after MRP (material requirements planning) determines the planned orders needed to complete demand, your suppliers should be issued purchase order releases. A robust automotive EDI solution, like AIM, will handle the EDI needs for the entire supply chain.

Summary

EDI is a vital component in the automotive supply chain. EDI Standards, however, come in many formats and versions which can be overwhelming for the supplier. AIM Computers has more than 30 years of automotive EDI experience. We handle all formats and communication protocols for more than 450 trading partners and integrate them into AIM Vision ERP, or your ERP solution.

Looking for help? Let’s talk about EDI so you can have more control over your supply chain.