The Benefits of ERP: Transforming Modern Business Operations

Enterprise Resource Planning (ERP) systems have become the backbone of modern manufacturing and supply chain operations. For automotive suppliers in particular, understanding the benefits of ERP is no longer optional—it’s essential for meeting OEM requirements, maintaining compliance, and protecting supplier scorecards. An ERP system brings together critical business functions such as finance, inventory, production, and supply chain management into a single, integrated platform, giving organizations real-time visibility and control across their operations.

For manufacturers and automotive suppliers in particular, the importance of ERP continues to grow as customer requirements, compliance standards, and supply chain complexity increase. Disconnected systems and manual processes make it difficult to manage demand changes, maintain accurate inventory, and ensure on-time delivery. This is where the benefits of an ERP system become clear: centralized data, automated workflows, and actionable insights that help teams make better decisions and operate more efficiently.

In this article, we’ll explore the benefits of enterprise resource planning, including how ERP supports enterprise resource planning and supply chain management, improves operational efficiency, and enables long-term business growth. Whether you’re evaluating ERP for the first time or looking to modernize existing systems, understanding why ERP is important is the first step toward building a more resilient, competitive organization.

What Is an ERP System?

An ERP system, or Enterprise Resource Planning system, is a centralized software platform designed to manage and integrate an organization’s core business processes in real time. Instead of relying on disconnected applications, spreadsheets, or manual workflows, ERP systems bring critical functions—such as finance, inventory management, production, purchasing, and supply chain operations—into a single, unified system.

These capabilities are especially critical when evaluating the benefits of ERP for automotive suppliers managing EDI schedules, cumulative accounting, barcode labeling, and just‑in‑time shipping.

At its core, an ERP system creates a shared database that all departments access and update. This ensures that everyone—from accounting and operations to shipping and supply chain teams—is working from the same accurate, up-to-date information. This centralized approach is a key reason why the benefits of an ERP system extend far beyond basic data management.

Modern ERP platforms are modular, meaning businesses can implement only the functionality they need while maintaining the ability to scale as operations grow. Common ERP modules include:

- Financial management and accounting

- Inventory and warehouse management

- Production and operations management

- Purchasing and supplier management

- Enterprise resource planning and supply chain management

- Reporting, dashboards, and business intelligence

For manufacturers and automotive suppliers, ERP systems play an especially critical role. Customer demand is often communicated electronically, production schedules change frequently, and compliance requirements are strict. Without an ERP system, managing cumulative demand, inventory accuracy, production planning, and shipping execution becomes increasingly difficult. This is why understanding what an ERP system is directly supports understanding the broader advantages of enterprise resource planning.

By connecting data, automating workflows, and enforcing standardized processes, ERP systems provide the foundation businesses need to operate efficiently, maintain compliance, and respond quickly to change—setting the stage for the full range of benefits of ERP explored in the next section.

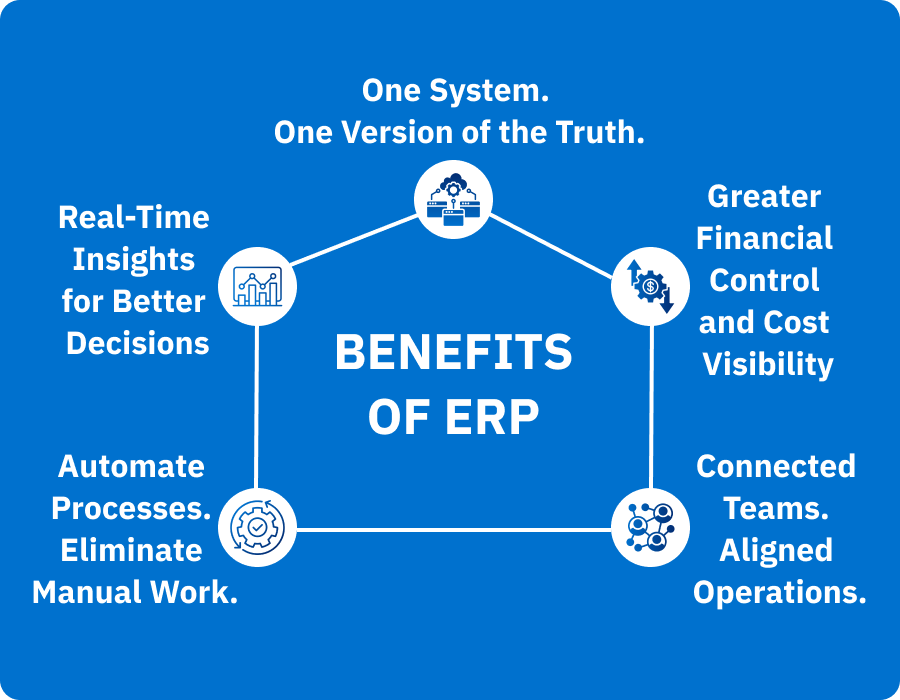

Core Benefits of ERP for Automotive Manufacturing

The true value of ERP lies in how it transforms the way a business operates day to day. By integrating systems, automating processes, and delivering real-time visibility, ERP systems provide measurable advantages across the organization. Below are the primary business benefits of an ERP system that drive efficiency, accuracy, and long-term growth.

A Single Source of Truth Across the Business

One of the most fundamental benefits of ERP is centralized data—an essential requirement for automotive suppliers managing OEM releases, cumulative quantities, and audit‑ready records. ERP systems eliminate information silos by storing all operational, financial, and supply chain data in one unified system.

Instead of teams relying on disconnected spreadsheets or department-specific software, everyone works from the same real-time data. This improves data accuracy, reduces duplicate entry, and ensures that decisions are based on consistent information across finance, operations, production, and supply chain management.

This single source of truth is foundational to the benefits of enterprise resource planning, especially for organizations managing complex operations.

Improved Decision-Making with Real-Time Visibility

ERP systems provide real-time dashboards, reports, and analytics that give leadership immediate insight into business performance. Whether monitoring inventory levels, production output, financial performance, or customer demand, ERP enables faster and more informed decisions.

This visibility is especially critical in enterprise resource planning and supply chain management, where demand changes, material shortages, or shipping delays can quickly impact operations. With ERP, teams can identify issues early and respond proactively instead of reacting after problems escalate.

For example, when an OEM updates an 830 or 862 schedule, ERP visibility allows suppliers to immediately assess inventory exposure, production impact, and shipping risk—one of the most practical benefits of ERP in automotive supply chains.

This capability answers a key question many organizations ask: what are the primary business benefits of an ERP system? Better decisions, made faster, with less risk.

Increased Operational Efficiency Through Automation

Another major advantage of enterprise resource planning is automation. ERP systems replace manual, time-consuming processes with automated workflows that reduce errors and improve speed.

Automation is one of the most measurable benefits of ERP, especially for suppliers processing high volumes of EDI, ASNs, and shipping documentation.

Common automation benefits include:

- Automated order processing and scheduling

- Streamlined purchasing and supplier coordination

- Faster invoicing and financial close processes

- Reduced manual data entry across departments

By eliminating repetitive tasks, ERP allows employees to focus on higher-value activities—driving productivity and efficiency across the organization. This is one of the most tangible benefits of using ERP for growing businesses.

Better Financial Control and Cost Management

ERP systems integrate financial data directly with operational activity, giving organizations greater control over costs, margins, and cash flow. Real-time visibility into expenses, inventory valuation, and production costs supports more accurate budgeting and forecasting.

Over time, this leads to:

- Reduced operational waste

- Improved cost tracking and accountability

- More predictable financial performance

These financial improvements are a key reason why the benefits of an ERP system extend beyond IT and into overall business strategy.

Stronger Collaboration Across Departments

Because ERP systems connect all core business functions, they naturally improve collaboration. Sales, operations, finance, and supply chain teams are no longer working in isolation or relying on outdated information.

Improved collaboration reduces miscommunication, shortens cycle times, and helps organizations operate as a single, aligned business—one of the often-overlooked advantages of enterprise resource planning.

In the next section, we’ll take a closer look at how these core ERP benefits apply specifically to enterprise resource planning and supply chain management, where ERP delivers some of its most powerful results.

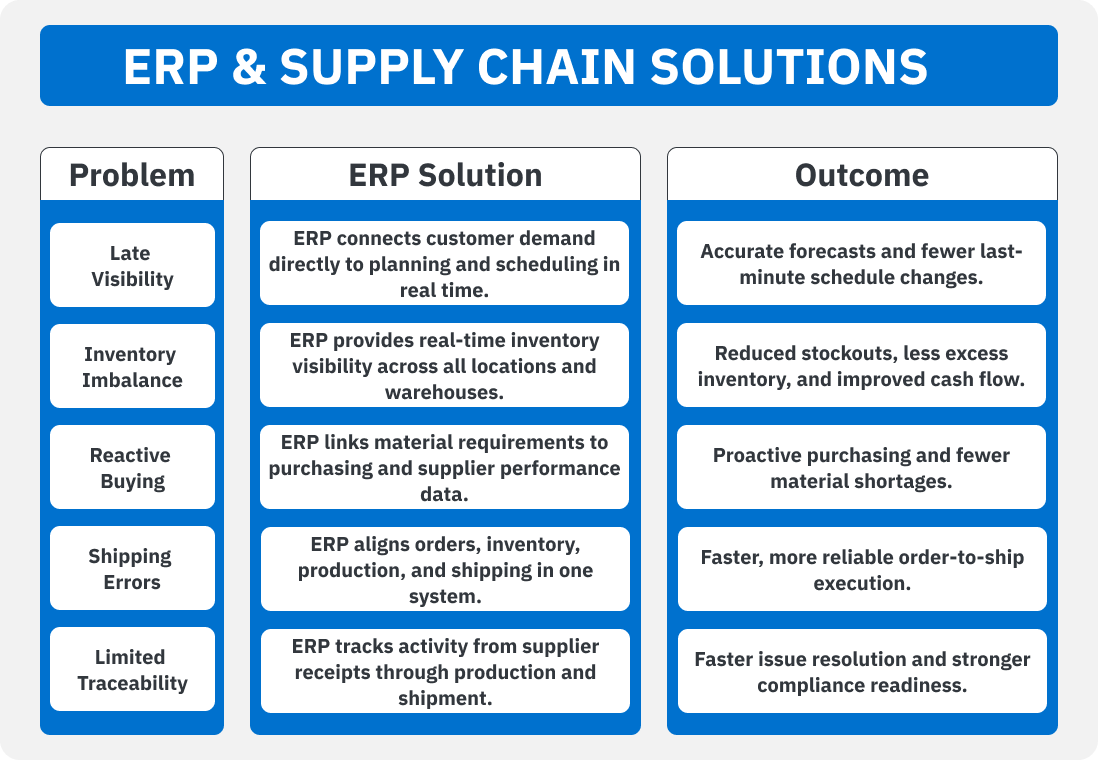

The Benefits of ERP and Supply Chain Management

When people talk about enterprise resource planning and supply chain management, they’re really talking about the same goal: keeping materials, production, and shipments moving with fewer surprises. An ERP system strengthens supply chain performance by connecting demand, inventory, purchasing, production, and shipping into one coordinated workflow—so teams can act on the same data, in real time.

Here are the most valuable ways ERP improves supply chain management (and why it’s one of the most practical benefits of using ERP):

More Accurate Demand Planning and Scheduling

Supply chains don’t break because of a single big issue—they break because small changes aren’t seen early enough. ERP helps by tying customer demand signals directly to planning and scheduling, so updates flow into production and procurement faster. The result is better forecasting, fewer last-minute expedites, and more stable schedules.

Inventory Optimization Without Guesswork

One of the biggest operational wins from ERP is improved control over inventory levels. With ERP, you can track inventory across warehouses and locations, understand what’s available versus allocated, and see usage trends—helping reduce stockouts and excess inventory. This is a direct contributor to cost control, cash flow improvement, and customer service performance.

Stronger Supplier and Purchasing Coordination

ERP streamlines purchasing by linking material requirements to procurement workflows. Instead of buyers reacting to shortages after the fact, ERP supports proactive purchasing based on real requirements—often with tools for supplier performance tracking (quality, delivery, responsiveness) that improve vendor accountability over time.

Faster, More Reliable Order-to-Ship Execution

Supply chain success depends on execution at the dock as much as it depends on planning. ERP systems help ensure that what gets built is what gets shipped—and that shipments align to customer requirements. When order management, inventory, and shipping execution share the same system and data, businesses reduce rework, shipping errors, and delivery delays.

End-to-End Visibility and Traceability

A major reason why ERP is important is visibility—especially when something goes wrong. ERP gives teams the ability to trace activity across the supply chain: from supplier receipts to production usage to finished goods shipments. This visibility supports faster root-cause analysis, improved customer responsiveness, and stronger compliance readiness (especially for manufacturers with strict customer or industry requirements).

For manufacturers and automotive suppliers, these benefits become even more critical because demand changes frequently, shipping requirements are strict, and mistakes can lead to chargebacks or delivery disruptions. Next, we’ll cover how ERP supports scalability and growth—and why the right ERP can become a long-term competitive advantage.

Scalability, Flexibility, and Growth Enablement

As companies grow, the cracks in disconnected systems get wider—more customers, more parts, more suppliers, more locations, and more complexity to manage. That’s where the importance of ERP becomes especially clear. One of the most strategic benefits of an ERP system is that it gives your business a foundation that can scale without forcing you to rebuild processes every time operations expand.

Scale Operations Without Scaling Chaos

Growth often adds complexity in predictable ways:

- More SKUs and engineering changes

- Higher transaction volume (orders, receipts, shipments, invoices)

- More production scheduling constraints

- More warehouses or plants

ERP helps absorb this growth by standardizing workflows and keeping data consistent across the organization. Instead of hiring more people to manage manual workarounds, ERP supports growth through automation and repeatable processes—one of the most valuable advantages of enterprise resource planning.

Add Capabilities Over Time

Modern ERP systems are typically modular, allowing organizations to implement what they need now and expand later. For example, a manufacturer may start with core financials, inventory, and production planning—and then add advanced scheduling, quality tracking, supply chain collaboration, or business intelligence as priorities evolve.

This flexibility is a major reason why ERP is important for companies that want to improve step-by-step while still keeping all data connected.

Support Multi-Plant and Multi-Warehouse Operations

As suppliers expand into multiple facilities, consistent processes become harder to maintain. ERP helps unify workflows across locations while still supporting local execution—such as facility-specific inventory, production resources, or shipping operations. Leadership gains centralized visibility while plant teams maintain the control they need to run daily operations efficiently.

Enable Faster Response to Market and Customer Changes

Growth isn’t just internal—it’s driven by customers and market shifts. When requirements change (pricing, lead times, schedules, labeling, shipping expectations), ERP gives teams the visibility and control to respond quickly. That responsiveness reduces disruption and helps protect customer performance metrics like on-time delivery and fill rate.

Create a Long-Term Platform for Continuous Improvement

ERP isn’t only about “running the business”—it’s also about improving it. With consistent data and standardized processes, companies can more easily measure KPIs, identify bottlenecks, and implement improvements across production, inventory, purchasing, and fulfillment.

That ongoing improvement cycle is a core part of the benefits of enterprise resource planning—and one of the biggest reasons ERP becomes a competitive advantage over time.

Better Customer Experience

ERP isn’t just an internal efficiency tool—it directly impacts what customers care about most: accurate orders, reliable delivery, and fast communication when something changes. One of the most overlooked benefits of ERP is how it improves the customer experience by tightening execution across order management, production, inventory, and shipping.

Faster, More Accurate Order Fulfillment

When customer demand, available inventory, production schedules, and shipping plans all live in one system, companies can fulfill orders faster and with fewer mistakes. ERP reduces the risk of:

- Shipping the wrong part or quantity

- Missing a required delivery date

- Delays caused by “where is the inventory?” confusion

That improved execution is a major benefit of an ERP system, especially for manufacturers and suppliers operating on tight delivery windows.

Clearer Communication and Fewer Fire Drills

Customers expect answers quickly: Is it shipping today? What’s the status? Can you confirm the promise date? ERP supports better responsiveness by giving teams real-time visibility into order status, production progress, inventory availability, and shipment details—without relying on phone calls, emails, or manual lookups across multiple systems.

This is a key reason why ERP is important for businesses that want to strengthen customer trust and reduce costly expediting.

More Reliable On-Time Delivery Performance

On-time delivery is rarely improved by working harder—it’s improved by planning better and executing consistently. ERP helps teams align demand planning, material availability, production scheduling, and shipping execution so deliveries become more predictable. Over time, that reliability strengthens customer relationships and improves scorecards and supplier performance evaluations.

Fewer Errors That Lead to Returns, Chargebacks, or Disputes

In many industries—especially automotive—small documentation or shipment errors can lead to major downstream impact. ERP improves data accuracy and process control so organizations reduce:

- Shipping and labeling errors

- Documentation inconsistencies

- Disputes around quantities, dates, and invoicing

This is one of the most practical advantages of enterprise resource planning because it protects revenue while improving customer satisfaction.

Regulatory Compliance and Risk Management

Compliance requirements and operational risk go hand in hand—especially for manufacturers managing complex supply chains, strict customer requirements, and frequent audits. One of the most important benefits of ERP is that it helps organizations reduce risk by standardizing processes, improving traceability, and creating a reliable digital record of what happened, when it happened, and who did it.

Below are the key ways the benefits of an ERP system support compliance and risk management.

Stronger Process Control and Standardization

Manual processes and disconnected systems create inconsistency—and inconsistency creates risk. ERP systems enforce standardized workflows across purchasing, production, inventory, shipping, and finance. That means fewer “workarounds,” fewer errors, and greater reliability across departments and locations.

This is a major reason why ERP is important as organizations scale: consistency becomes harder to maintain without a system built to control and coordinate processes.

Audit Trails and Accountability

ERP systems create a built-in audit trail for critical transactions. Whether it’s a material receipt, inventory adjustment, production posting, or shipment confirmation, ERP provides time-stamped records that improve accountability and reduce disputes.

When issues arise—inventory variances, delivery disputes, customer complaints—ERP makes it easier to investigate quickly and accurately. That speed matters because it reduces downtime, reduces exposure, and improves customer responsiveness.

Traceability for Quality and Recall Readiness

For manufacturers, traceability is not just a “nice to have.” It’s often a requirement. ERP supports traceability by linking material movement and production activity to finished goods—helping organizations trace components, lots, and processes when quality issues occur.

This is one of the most valuable benefits of enterprise resource planning for organizations that need to meet strict customer and industry expectations for quality control and containment.

Reduced Financial and Operational Risk

ERP reduces risk by improving:

- Inventory accuracy (reducing stockouts, overproduction, and write-offs)

- Cost control and margin visibility

- Order accuracy and fulfillment reliability

- Security around access to sensitive business data

In practical terms, ERP helps organizations avoid costly mistakes that show up as rework, expediting, missed shipments, billing errors, or customer penalties.

Better Security and Data Governance

ERP systems help businesses manage data access through role-based permissions and centralized governance. Instead of critical business data being spread across personal spreadsheets, email chains, or standalone databases, ERP keeps information managed, controlled, and protected—reducing both operational disruption and compliance exposure.

Challenges to Consider (and How to Avoid Them)

It’s easy to focus only on the benefits of ERP system upgrades—but to get the full value, you also need to plan for the realities of selection, rollout, and adoption. The good news: most ERP challenges are predictable, and with the right approach, they’re avoidable.

Below are the most common hurdles organizations face and practical ways to overcome them—while still capturing the long-term advantages of enterprise resource planning.

Change Management and User Adoption

The challenge: Even the best ERP won’t deliver results if teams don’t use it correctly. Resistance often shows up when workflows change, screens look unfamiliar, or employees feel the system adds work instead of removing it.

How to avoid it:

- Involve end users early (operations, shipping, purchasing, finance—not just IT)

- Train by role and real workflows, not generic software demos

- Document “new way of working” processes so people don’t fall back on spreadsheets

Poor Data Quality Going In

The challenge: ERP systems don’t magically fix bad data. If part masters, routings, BOMs, inventory balances, or supplier/customer records are inconsistent, ERP will expose the problem fast—and that can cause planning and fulfillment issues.

How to avoid it:

- Clean and standardize master data before go-live

- Assign ownership for key data areas (inventory, purchasing, production, finance)

- Validate data with real scenarios (not just “does it import?”)

Underestimating Process Complexity

The challenge: Many companies underestimate how many “exceptions” exist in real operations—customer-specific requirements, packaging rules, shipping constraints, split shipments, substitute materials, etc. ERP implementations fail when the plan assumes everything is “standard.”

How to avoid it:

- Map current processes honestly, including exceptions and edge cases

- Test with real transactions (rush orders, backorders, partial receipts, schedule changes)

- Prioritize operational fit over flashy features during selection

Customization That Becomes a Long-Term Burden

The challenge: Heavy customization can make upgrades painful and expensive, and can lock the organization into brittle workflows.

How to avoid it:

- Favor configuration over customization whenever possible

- Use proven industry workflows and best practices

- Select ERP solutions that already align with your manufacturing and supply chain needs (especially for regulated or customer-driven industries)

Unrealistic Timelines or Lack of Internal Resources

The challenge: ERP projects stall when internal teams don’t have time to support testing, training, process decisions, and go-live prep—especially during peak production periods.

How to avoid it:

- Build implementation around your production calendar

- Assign internal owners for each functional area

- Create clear milestones for testing, training, and readiness—not just “go-live date”

How to Measure the ROI and Long-Term Value of ERP

The benefits of ERP are easiest to justify when you can measure them. Beyond “we feel more organized,” ERP ROI shows up in hard metrics: faster cycle times, fewer errors, better inventory performance, and improved cash flow. If you’re asking what are the primary business benefits of an ERP system, the best answer is: the ones you can prove with KPIs tied to your operations, finance, and supply chain.

Below are practical ways to measure the benefits of an ERP system—both immediately after go-live and over the long term.

Operational Efficiency KPIs

These metrics reveal whether ERP is actually reducing manual work and speeding execution:

- Order-to-ship cycle time (days/hours from order release to shipment)

- Schedule adherence (planned vs. actual production performance)

- Labor productivity (output per labor hour, overtime reduction)

- Rework and corrective actions tied to process errors

ROI signal: You’re doing the same work with fewer touches—and fewer fire drills.

Inventory and Supply Chain Performance KPIs

ERP value often shows up most clearly in inventory accuracy and material flow:

- Inventory accuracy % (system vs. physical)

- Inventory turns and reduction in slow-moving/obsolete inventory

- Stockout frequency and material shortage-driven downtime

- Supplier on-time delivery and purchase order cycle time

- Expedite costs (premium freight, unplanned purchases)

ROI signal: Less cash tied up in inventory, fewer shortages, and fewer expediting costs.

Customer Service and Delivery KPIs

Because ERP connects planning and execution, it should improve customer-facing outcomes:

- On-time delivery % (OTD)

- Perfect order rate (right part, right quantity, right documentation, on time)

- Return/claim rates caused by shipping or order errors

- Customer response time for order status and delivery questions

ROI signal: Fewer disputes and stronger customer scorecard performance.

Financial Performance KPIs

ERP strengthens financial control by tying transactions directly to operational reality:

- Days Sales Outstanding (DSO) and invoicing cycle time

- Month-end close time (days to close financials)

- Margin accuracy by product/customer (actual vs. estimated costs)

- Write-offs and adjustments from inventory or billing errors

ROI signal: Faster closes, cleaner billing, and clearer profitability insights.

A Simple ROI Framework You Can Use

A practical way to quantify ERP ROI is to total the measurable gains in three buckets:

- Cost reduction

- Reduced labor time (fewer manual tasks)

- Fewer expedites and premium freight

- Lower inventory carrying costs

- Reduced rework, scrap, and errors

- Risk reduction

- Fewer compliance issues, disputes, and preventable disruptions

- Better traceability and faster issue resolution

- Revenue enablement

- Higher on-time delivery → improved customer retention

- Ability to take on new business without adding headcount at the same rate

Even conservative improvements (for example, reducing expedite spend or shortening close time) can often justify the investment when tracked consistently.

Conclusion

The benefits of ERP go far beyond operational efficiency. For automotive suppliers, ERP is a foundation for compliance, visibility, and long‑term growth in an increasingly demanding supply chain environment. The right ERP solution doesn’t just manage transactions—it protects customer relationships, supports MMOG/LE and IATF 16949 compliance, and enables confident decision‑making as complexity increases.

For manufacturers and suppliers, the importance of ERP lies in its ability to reduce friction across operations. ERP systems help eliminate data silos, automate manual workflows, improve inventory accuracy, and align production and shipping with real customer demand. Over time, these improvements translate into stronger on-time delivery performance, lower operational risk, improved customer satisfaction, and a more scalable foundation for growth.

If you’ve been asking why ERP is important, the answer is clear: ERP enables businesses to operate with greater control, predictability, and efficiency in an increasingly complex and competitive environment. Whether you are evaluating ERP for the first time or considering an upgrade, understanding the benefits of an ERP system is the first step toward building a more resilient, compliant, and high-performing organization.

Ready to See the Benefits of ERP in Action?

If you’re evaluating how an ERP system could improve efficiency, accuracy, and supply chain performance, the next step is understanding what that looks like in your own operation. An ERP assessment or guided conversation can help you identify where disconnected systems, manual processes, or limited visibility are holding you back—and where the right ERP approach can deliver the greatest impact. Explore how a purpose-built ERP solution can support your business goals today and scale with you tomorrow.