AIM Mobility Dock Audit App

The AIM Mobility Dock Audit App, from AIM Vision ERP’s suite of manufacturing productivity apps, assists in enforcing quality inspections for paperwork that is required for such things as GP12 containment audit or prototype builds. The dock audit requirement can be established by item number, destination or order, and will prevent shipping paperwork from being printed and restrict the shipper / ASN from being updated until the shipper dock audit has been performed from a handheld tablet.

How the AIM Mobility Dock Audit Works

The AIM Mobility Dock Audit and its companion Alerts has three main purposes. Manufacturers use it to:

- Advise quality department that there are shipments requiring their review at the shipping dock

- Prevent shipping paperwork from being updated prior to a quality department review at the shipping dock

- Inform shipping department that the dock audit review has been completed and the shipping paperwork can be printed and the shipper can be updated

![]()

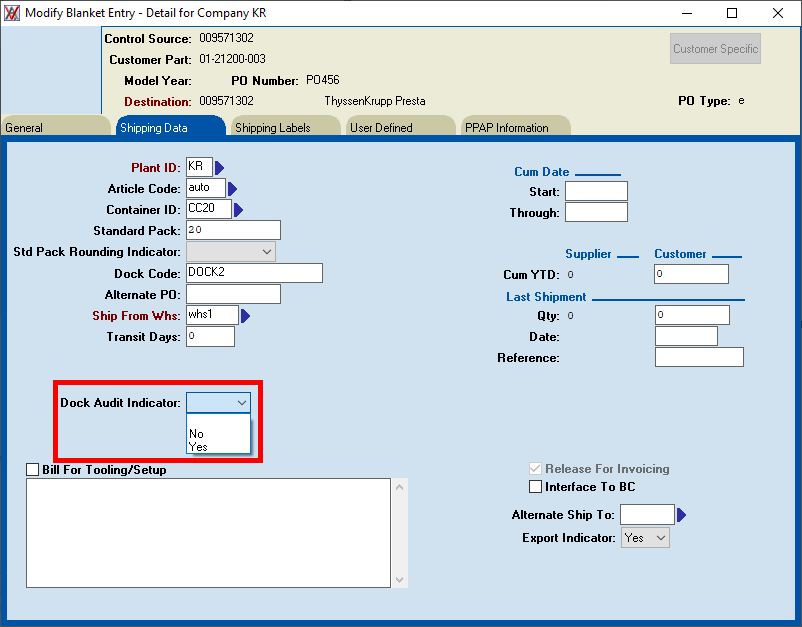

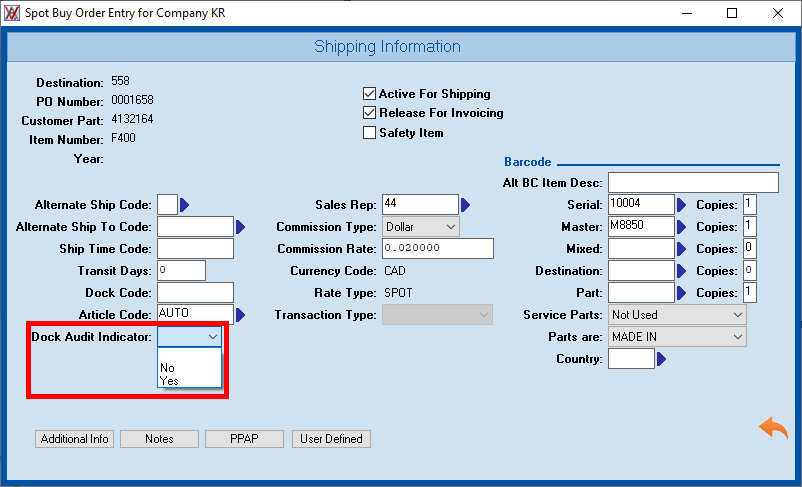

Setting up the Dock Audit Indicator

The Dock Audit Indicator resides on the blanket order detail and spot buy order detail window. Dock Auditing can be turned on by an individual order and line item basis from either of these options.

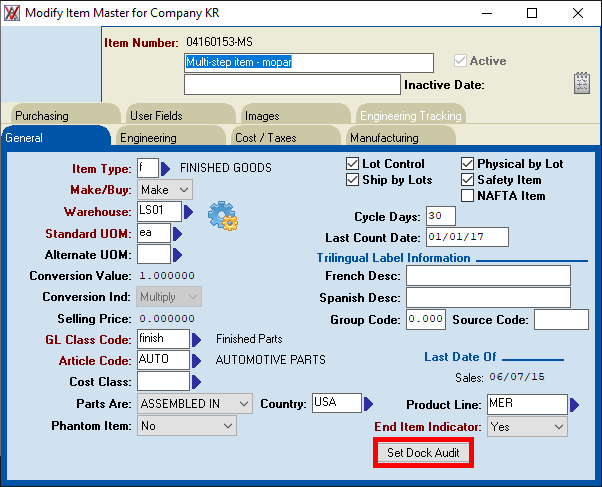

Quality managers can also choose to set the Dock Audit Indicator for all orders for a particular item number by selecting the Set Dock Audit button from the Modify mode in the Item Master Entry option.

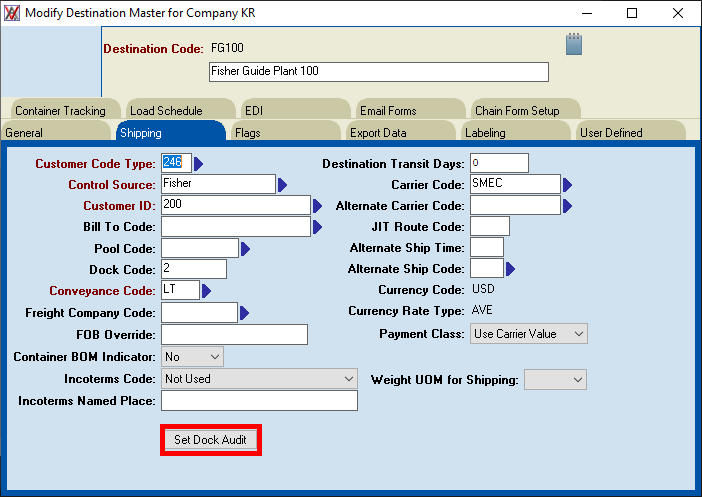

Similarly, they can choose to set the Dock Audit Indicator for all orders for a particular destination or ship to address by selecting the Set Dock Audit button from the Modify mode in the Destination Master file maintenance option.

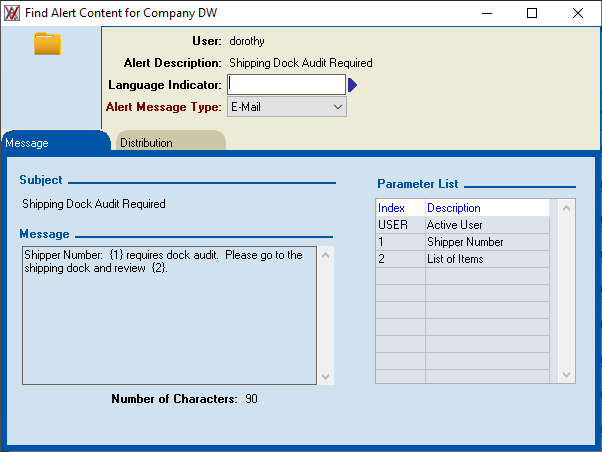

Defining the Dock Audit Required Alert

Utilizing the AIM Vision Alerts, an alert can be setup to email specified user IDs that a shipment needs to be audited to facilitate the auditing process. The message should be defined to include the Shipper Number and list of item numbers requiring audit. It can be defined to include additional general audit instructions.

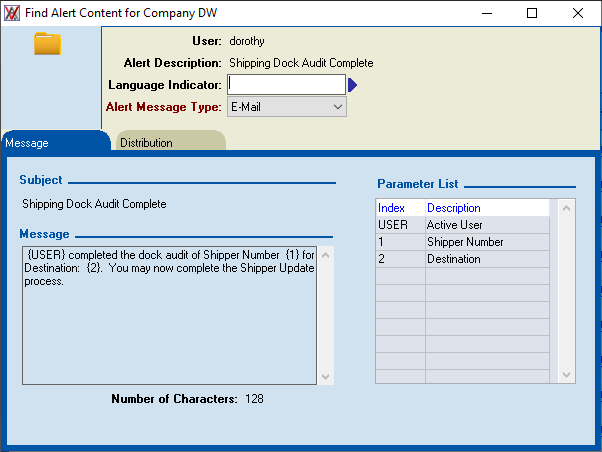

Defining the Dock Audit Complete Alert

A second alert can be setup, via the AIM Vision Alerts, to email specified user IDs that the dock audit process has been completed for a shipment, and that paperwork can be prepared and product shipped.

The message should be defined to include the Shipper Number and Destination that has completed the dock audit process. It can be defined to include the User ID of the person who completed the Dock Audit, and any additional general instructions.

Once the message content has been defined this alert can be assigned to a distribution list of users responsible for performing the shipping processes.

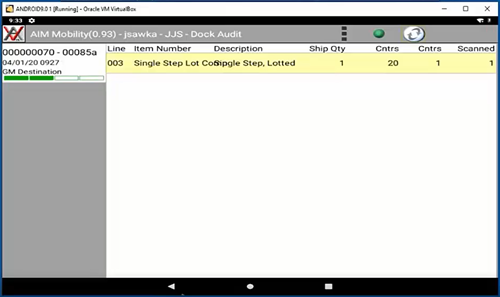

Performing a Dock Audit

Once the Dock Audit App is launched from the tablet, users will see any shipments requiring dock audit listed on the left side. After the quality department resource has completed their specific auditing requirements, a simple selection of the line item (yellow row in image below) will remove the item from the Dock Audit App. This, in turn, triggers the Shipping Dock Audit Complete Alert to be sent to the distribution list of users who can then complete the printing of the shipping paperwork, updating the shipper and sending the ASN.

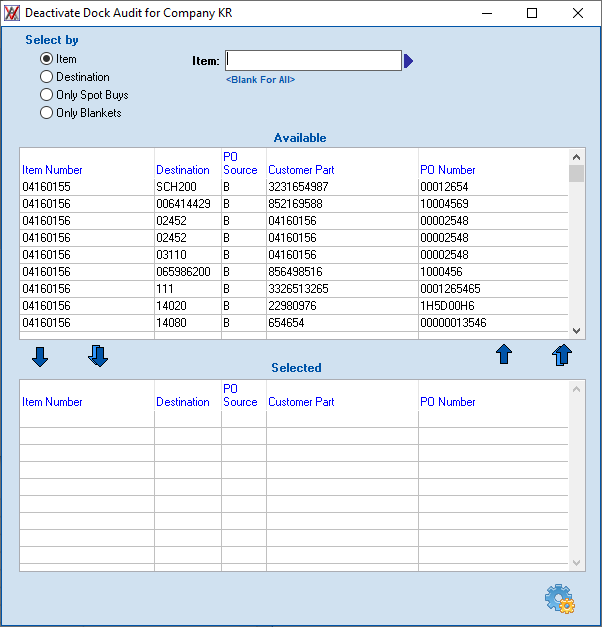

Deactivating Dock Audit

If GP12 Containment Audits are no longer necessary, or you have moved from prototype to production you may want to deactivate this dock auditing process. The Deactivate Dock Audit option can be used to turn the Dock Audit Indicator in the Blanket Entry Detail and spot Buy Detail from Yes to No.

This option gives the user the ability to select records by item number, destination, only spot buy orders or only blanket orders. Selecting records in the ‘Available’ browse to move them to the ‘Selected’ browse builds a list of records that will be deactivated once the utility is processed.

Watch the entire AIM Mobility Dock Audit app video.

Next Steps

Looking for help with GP12 containment and prototype paperwork auditing processing. Let’s talk about AIM mobility apps that make dock auditing easier and more efficient.