ERP Implementation Methodology for Automotive Suppliers

Implementing a new ERP system is one of the most transformative — and inherently high-risk — initiatives an automotive supplier can undertake. ERP implementations impact every part of your business, from EDI and order management to production scheduling, traceability, labeling, and shipping compliance. Without the right implementation methods, projects can easily run over budget, miss deadlines, or fail to deliver the improvements your team expects.

That’s why AIM uses a proven ERP implementation methodology tailored specifically for the automotive supply chain. Our structured approach removes uncertainty, accelerates adoption, and ensures your new system supports MMOG/LE, IATF 16949, AIAG labeling, and OEM-specific business logic from day one.

If you’ve ever wondered “What is implementation management?” or how leading suppliers reduce risk during ERP transformation, you’re in the right place. AIM’s methodology of ERP implementation blends best-practice project management with decades of automotive expertise — delivering predictable, measurable results.

What You’ll Learn on This Page:

- The ERP implementation approaches and methodology AIM uses to drive on-time, on-budget success

- How our structured process aligns people, data, workflows, and OEM requirements for predictable outcomes

- Why suppliers choose AIM when accuracy, compliance, and operational efficiency matter

What Makes AIM’s Implementation Method Different?

Most ERP vendors talk about their implementation process — but automotive suppliers know that not all ERP implementation approaches and methodology are created with automotive suppliers in mind. The automotive industry has unique demands: OEM-specific EDI logic, AIAG-compliant labeling, MMOG/LE expectations, cumulative accounting, sequence shipping, Kanban workflows, and strict audit and traceability requirements.

AIM’s ERP implementation methodology stands apart because it was built inside the automotive supply chain — not adapted to it. For more than 30 years, AIM has refined its implementation methods through real-world experience with Tier 1–3 suppliers, high-volume production environments, and thousands of OEM trading-partner combinations.

Below are the core elements that make AIM’s methodology of ERP implementation uniquely effective.

Why Implementation Methodology Matters

Implementing an ERP system isn’t just a software project — it’s a transformation of how your business operates. For automotive suppliers, where accuracy, compliance, and efficiency directly impact OEM scorecards and customer satisfaction, the process of implementing ERP must be structured, predictable, and aligned to industry-specific requirements.

A well-defined ERP implementation methodology ensures every phase of the project supports business goals, reduces risk, and enables your team to adopt the system with confidence. Without a clear approach, companies face the most common failure points: misaligned expectations, poor data migration, costly rework, missed deadlines, and downstream operational disruptions.

This is where strong implementation management becomes essential.

Why a Structured Methodology of ERP Implementation Is Critical

Clear milestones, documented deliverables, and defined sign-offs ensure that the project stays on track. The right implementation methods prevent confusion, eliminate guessing, and replace reactive problem-solving with proactive planning.

Automotive suppliers require more than generic roadmaps. AIM’s ERP implementation approaches and methodology consider OEM labeling rules, MMOG/LE expectations, IATF requirements, cumulative accounting, Kanban logic, and release management. This prevents costly misconfigurations later.

Successful ERP adoption requires cooperation across shipping, production, quality, finance, IT, and customer service. The right methodology includes structured communication, training, and hands-on validation so every department is ready for go-live.

A disciplined methodology of ERP implementation leads to tangible outcomes:

- Higher inventory accuracy

- Fewer labeling and ASN errors

- Improved on-time delivery

- Greater visibility into production, demand, and costs

- Stronger audit performance (MMOG/LE, IATF)

A system implemented correctly today will continue to support new OEM requirements, trading partners, plant expansions, and process changes tomorrow. Strong ERP implementation approaches ensure your foundation is solid and adaptable.

A disciplined ERP implementation methodology isn’t optional — it’s the backbone of a successful transformation. When done correctly, it minimizes disruption, maximizes adoption, and ensures your ERP becomes a strategic advantage rather than a burden.

Our Step-by-Step ERP Implementation Approaches and Methodology

AIM’s ERP implementation methodology is built specifically for automotive suppliers who operate in high-pressure, compliance-driven environments. Unlike generic consulting frameworks, our methodology reflects 30+ years of real-world experience with OEM mandates, EDI requirements, bar code labeling, cumulative accounting, and complex shipping workflows.

Below is a detailed look at our structured process of implementing an ERP solution using best-practice implementation methods and strong implementation management.

-

1. Prepare — Establish the Foundation for SuccessThe first step in any successful ERP initiative is clarity. We begin by defining scope, reviewing your current processes, identifying pain points, and aligning on expected outcomes.

During this stage we:- Evaluate existing systems and workflows

- Identify MMOG/LE, IATF, and customer-specific compliance requirements

- Clarify project goals, risks, constraints, and timeline expectations

This stage eliminates ambiguity and ensures every downstream decision supports real business goals. -

2. Plan — Build a Roadmap Aligned to Your OperationsAIM develops a detailed project plan that outlines tasks, ownership, responsibilities, and milestones. This is where implementation management becomes crucial: timelines, resources, data requirements, and departmental responsibilities are clearly defined.

The Plan phase includes:- Customizing the “Gold Star” workflow for your facility

- Designing a data migration strategy

- Establishing communication channels and progress reporting

- Scheduling training, testing, and validation activities

This phase anchors the project in documented, shared expectations—preventing drift and costly rework. -

3. Design — Configure the System to Match Your ProcessesAutomotive suppliers rarely fit neatly into generic ERP templates. AIM’s implementation team configures the system using proven ERP implementation approaches and methodology, including:

- EDI logic for 500+ trading partners

- Customer-specific AIAG bar code label formats

- CUM management, release accounting, and RAN logic

- Kanban, ILVS, and sequence shipping workflows

- Shop floor data capture with Mobility MES

- Production scheduling via MRP/CRP and Digital Whiteboard

This is where AIM’s prebuilt OEM logic and AIAG labeling expertise accelerate setup and reduce customization. -

4. Validate — Test, Train, and Confirm ReadinessValidation is where AIM eliminates risk before go-live. Through a Conference Room Pilot (CRP), your team simulates real operational workflows end-to-end. This is a cornerstone of AIM’s proven implementation methodology.

During Validate we:- Test customer releases, CUM logic, scheduling, and shipping

- Confirm label formats and ASN accuracy

- Validate production posting, inventory movement, and outside processing

- Train users and refine role-based workflows

- Identify and correct issues early, reducing go-live risk

Validation reduces go-live risk by uncovering issues early—before they impact customer shipments. -

5. Deploy — Launch With ConfidenceThe final step of our process of implementing ERP is the transition to live operations. AIM’s team works alongside your staff on the production floor, shipping dock, and administrative offices to ensure a smooth rollout.

Deployment includes:- Final system cutover

- Live monitoring of transactions, EDI, and labeling

- Hypercare support for rapid issue resolution

- Confirmation that all departments meet MMOG/LE and OEM expectations

- Transition to long-term support and continuous improvement

AIM’s on-site and remote hypercare ensures suppliers meet OEM shipping, labeling, and ASN standards on Day 1.

Why This Methodology Works

AIM’s approach is built on:

- Automotive-specific expertise

- Proven project discipline

- Clear communication and sign-offs

- Deep understanding of supplier workflows

- Strong implementation management

- Real results — improved accuracy, reduced errors, higher compliance, and stronger customer scorecards

This is not just another ERP implementation methodology—it is a purpose-built framework engineered for the automotive supply chain. AIM’s methodology is backed by software platforms built specifically for automotive—AIM AutoSys, AIM AutoCOR, and AIM Vision—which embed OEM business rules directly into the system.

Automotive-Specific Expertise — Not Generic ERP Consulting

Most ERP providers offer broad, industry-agnostic frameworks. AIM delivers an implementation methodology backed by automotive specialists who understand your customer scorecards, labeling specs, compliance obligations, and production realities.

We speak the language of automotive operations—because we’ve lived it for more than 30 years.

- 830/862 release management

- CUM reconciliation

- RAN logic

- ILVS and sequence shipping

- Toyota Shipping Confirmation

- Honda Line-Side labeling

- MMOG/LE and IATF requirements

This depth of expertise eliminates guesswork — a critical differentiator in implementation management.

A Proven Five-Stage Framework Backed by Project Discipline

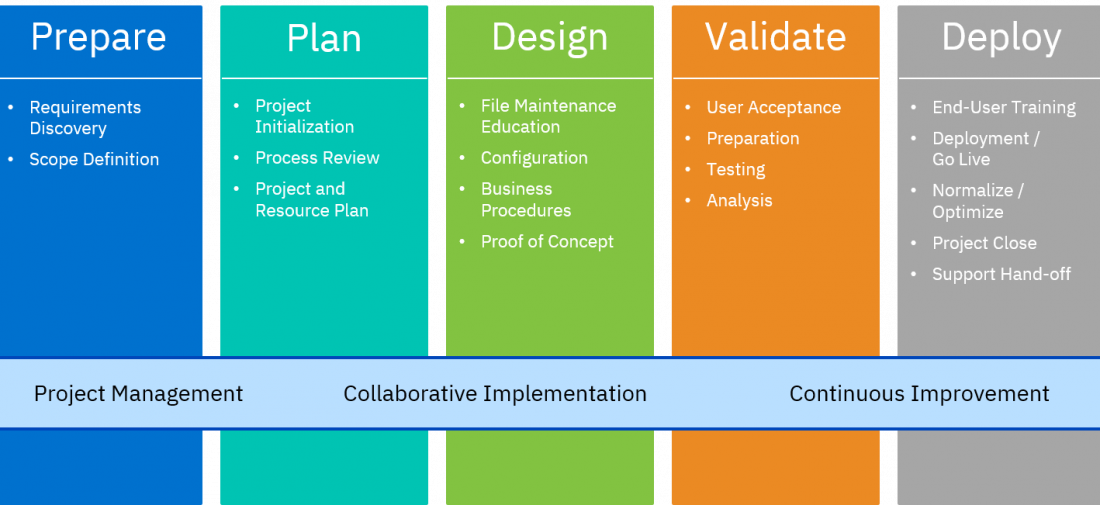

AIM’s structured ERP implementation approaches — Prepare → Plan → Design → Validate → Deploy — provide clarity and predictability throughout the project.

Every phase includes:

- Documented deliverables

- Risk reviews

- Sign-offs

- Milestone tracking

- Communication checkpoints

This disciplined methodology ensures your project stays on time, within scope, and aligned with business goals. This level of discipline ensures suppliers maintain accuracy, compliance, and audit readiness throughout the lifecycle of the system.

Embedded OEM Business Logic That Reduces Customization

Unlike traditional ERP projects that require expensive custom coding, AIM’s systems include:

- Preconfigured EDI logic for 500+ trading partners

- 2,000+ customer-specific AIAG label formats

- Built-in rules for ASN validation

- Automotive best-practice workflows

This dramatically reduces implementation time, cost, and complexity — one of the biggest advantages of AIM’s ERP implementation approaches and methodology.

Deep Collaboration Between AIM Experts and Your Team

A successful ERP roll-out depends on cross-department engagement. AIM’s collaborative implementation style ensures Shipping, Production, Quality, IT, Finance, Purchasing, and Leadership all move in sync.

Our experts work side-by-side with your team to:

- Document processes

- Provide hands-on training

- Conduct Conference Room Pilot sessions

- Validate real-world workflows

- Prepare users for go-live

This people-first approach strengthens adoption and accelerates ROI.

Emphasis on Validation and Risk Mitigation Before Go-Live

Most ERP failures occur because organizations skip or rush testing. AIM’s methodology makes the Validate phase non-negotiable.

Our Conference Room Pilot (CRP) simulates real daily operations across:

- Shipping and labeling

- EDI inbound/outbound

- Production posting

- Inventory movement

- Outside processing

- Scheduling

By the time go-live arrives, your team operates with confidence — not uncertainty.

Post-Go-Live Support and Continuous Improvement

The go-live moment isn’t the end — it’s the beginning of optimization. AIM provides:

- On-site or remote hypercare

- Performance monitoring

- Issue resolution

- Best-practice recommendations

- Transition to long-term support

Continuous improvement is woven directly into our methodology of ERP implementation, ensuring your system evolves alongside your business.

How AIM Ensures Implementation Success

Successful ERP transformation requires more than just a strong ERP implementation methodology—it requires the right partnership. Every AIM project is led by a dedicated AIM Project Manager who guides your team from kickoff through go-live, ensuring a smooth transition from your legacy system to your new ERP environment.

Here’s how AIM’s implementation management ensures success:

Clear Goals and Objectives

We align your business needs with the ERP implementation methodology from day one.

Custom Implementation Plan

A tailored roadmap built around your processes, trading partners, and requirements.

Effective Scheduling

Structured timelines and coordinated resources to keep the project on track.

Comprehensive Training

Role-based education that prepares every user for go-live success.

Regular Progress Updates

Transparent communication with ongoing status reports and milestone checkpoints.

Ready to Transform Your ERP Implementation?

Implementing an ERP system is too important to leave to chance. With AIM’s proven ERP implementation methodology, you get a structured, automotive-focused approach that delivers accuracy, compliance, and operational efficiency from day one.

Ready to reduce risk, accelerate go-live, and ensure OEM compliance from Day 1?

Schedule a strategy session with AIM’s implementation experts.

Frequently Asked Questions

What is an ERP implementation methodology?

An ERP implementation methodology is the structured framework used to guide the planning, configuration, testing, and deployment of a new ERP system. AIM’s methodology is built specifically for automotive suppliers and includes five phases: Prepare, Plan, Design, Validate, and Deploy.

What is the process of implementing an ERP system?

The process of implementing ERP typically includes goal setting, process review, system configuration, user training, testing, data migration, and go-live support. AIM’s structured approach ensures each phase is aligned with your operational needs and OEM compliance requirements.

Why does implementation management matter?

Implementation management ensures your ERP project stays on time, within scope, and properly aligned with your business processes. Strong management reduces risk, prevents disruptions, and improves user adoption.

What makes AIM’s implementation methods different?

AIM uses automotive-specific implementation methods that incorporate EDI logic, AIAG labeling requirements, cumulative accounting, Kanban workflows, and MMOG/LE/IATF compliance. This eliminates costly customization and dramatically accelerates deployment.

What ERP implementation approaches work best for automotive suppliers?

Automotive suppliers need ERP implementation approaches that support release accounting, labeling compliance, real-time visibility, traceability, and accurate shipping. AIM’s approach is specifically engineered for the automotive supply chain.

How long does an ERP implementation typically take?

Implementation timelines vary based on system scope, training needs, data readiness, and the complexity of workflows. AIM’s clear scheduling, phased methodology, and project management help ensure on-time delivery.

How involved does my team need to be during implementation?

Your team’s involvement is essential. AIM collaborates closely with Shipping, Production, Quality, Finance, IT, and Leadership to validate workflows, configure the system correctly, and ensure strong user adoption at go-live.

Will AIM provide training as part of the implementation?

Yes. Comprehensive, role-based training is a core component of AIM’s methodology of ERP implementation. Your team receives guided instruction, hands-on practice, and clear documentation before go-live.

What happens after go-live?

AIM provides hypercare support, performance monitoring, optimization recommendations, and a seamless transition to long-term support. Continuous improvement is a built-in part of our ERP implementation approaches and methodology.

How do I know if AIM’s ERP implementation methodology is right for my company?

If you’re an automotive supplier seeking structured, compliant, automotive-specific ERP deployment with reduced risk and faster results, AIM’s implementation methodology is an ideal fit.