EDI Inventory Management: How Modern EDI Systems Improve Inventory Accuracy and Visibility

Inventory has always been a balancing act, but for today’s manufacturers and suppliers, the margin for error is shrinking fast. Shortages, excess stock, inaccurate counts, and delayed updates between trading partners don’t just create inefficiencies—they disrupt production schedules, damage customer relationships, and increase costs across the supply chain. That’s why EDI inventory management has become a foundational capability for companies operating in complex, high-volume supply chains.

At its core, EDI in inventory management replaces slow, manual updates with automated, system-to-system communication. Instead of relying on spreadsheets, emails, or delayed portal updates, inventory data flows electronically and consistently between suppliers, manufacturers, warehouses, and customers. The result is faster visibility into what’s on hand, what’s committed, and what needs to be replenished—without human rekeying or guesswork.

An effective EDI inventory system goes beyond basic data exchange. It creates a shared, trusted view of inventory across trading partners, enabling better planning, tighter coordination, and fewer surprises. When paired with the right EDI inventory management software, organizations can turn raw inventory messages into actionable insight that supports production planning, order fulfillment, and customer service.

In this guide, we’ll break down what EDI inventory management really is, how EDI inventory systems work, and what to look for in software that supports real-world inventory challenges. We’ll also explore best practices, common pitfalls, and where EDI-driven inventory management is headed as supply chains demand greater speed, accuracy, and resilience.

What Is EDI Inventory Management?

EDI inventory management refers to the automated exchange of inventory data between trading partners using Electronic Data Interchange, without manual entry or intervention. Instead of updating inventory through spreadsheets, emails, or customer portals, inventory positions are communicated system-to-system in a standardized, structured format that both sides can trust.

In practical terms, EDI in inventory management allows inventory levels, availability, and status to be shared electronically between suppliers, manufacturers, warehouses, and customers. These updates can include what is currently on hand, what has been allocated to open orders, what is in transit, and what is expected to arrive. Because the data moves directly between systems, inventory information stays aligned across the supply chain—even when volumes are high or demand changes quickly.

An EDI inventory system acts as the bridge between external trading partners and internal systems like ERP, WMS, or production planning tools. When inventory changes inside one system, EDI transactions communicate those changes outward in near real time. Likewise, when a customer or supplier sends updated inventory-related data, it flows straight into internal planning and execution processes without rekeying or interpretation.

This is where EDI inventory management differs from traditional inventory tracking. Manual methods often introduce delays, mismatches, and errors, especially when multiple parties rely on the same data to make decisions. EDI replaces those weak points with consistency and speed. Inventory updates follow agreed-upon standards and business rules, ensuring that every partner is working from the same version of the truth.

When supported by the right EDI inventory management software, this approach doesn’t just move data—it enforces validation, monitors exceptions, and ties inventory visibility directly into ordering, shipping, and production workflows. The result is tighter control over inventory, better coordination with trading partners, and fewer surprises that disrupt operations.

Core Components of an EDI Inventory System

A successful EDI inventory system is not just about sending and receiving files. It’s a coordinated set of components that work together to keep inventory data accurate, timely, and usable across internal teams and external trading partners. Understanding these components helps clarify why some EDI initiatives deliver real inventory control while others fall short.

At the heart of EDI inventory management are inventory-specific EDI transactions. The most common example is the Inventory Inquiry/Advice message, which communicates current stock positions and availability. These messages can reflect on-hand quantities, committed inventory, items in transit, and projected availability. When exchanged consistently, they give both sides of the supply chain a shared view of inventory reality rather than assumptions based on outdated reports.

Equally important is integration with internal systems. An EDI inventory system must connect directly to the systems that actually manage inventory—typically an ERP, warehouse management system (WMS), or production planning system. Inventory updates generated on the shop floor or in the warehouse need to flow outward through EDI, while inbound inventory data from customers or suppliers must feed planning, replenishment, and fulfillment processes automatically. Without this tight integration, EDI becomes an isolated communication tool instead of a driver of operational accuracy.

Another critical component is data validation and business logic. Inventory data is only valuable if it’s reliable. EDI inventory management software applies rules that validate quantities, locations, units of measure, and timing before data is accepted or transmitted. These controls prevent common issues such as negative inventory positions, mismatched item identifiers, or outdated availability being shared with customers. Over time, this consistency builds trust in the inventory data across organizations.

Finally, effective systems include monitoring, visibility, and exception handling. Inventory changes don’t always go as planned—shipments get delayed, counts get adjusted, and demand spikes unexpectedly. An EDI inventory system should make these exceptions visible, alert the right teams, and allow quick corrective action. Instead of discovering problems days later through manual reconciliation, teams can respond in near real time.

Together, these components transform EDI from a basic data exchange into a true inventory management capability. In the next section, we’ll look at why dedicated EDI inventory management software plays such a critical role in turning these components into measurable business results.

Why EDI Inventory Management Software Matters

While EDI standards define how inventory data is exchanged, it’s the EDI inventory management software that determines whether that data actually improves day-to-day operations. Without the right software layer, inventory messages remain raw data—useful in theory, but disconnected from planning, fulfillment, and production decisions.

Turning Inventory Data Into Usable Intelligence

Inventory-related EDI messages can arrive frequently and in large volumes, especially in automotive and manufacturing environments. EDI inventory management software interprets those messages, applies business rules, and translates them into meaningful inventory updates inside your ERP or warehouse system. Instead of simply showing quantities, the software clarifies what inventory is available to promise, what is already allocated, and what inventory changes require action.

This translation layer is what allows inventory data to support smarter decisions. Planners can rely on accurate availability, customer service teams can commit to realistic ship dates, and production teams can align schedules with actual material status rather than assumptions.

Real-Time Visibility Across Trading Partners

One of the biggest advantages of EDI in inventory management is speed, but speed alone isn’t enough. Inventory updates must be timely and consistent across organizations. EDI inventory management software ensures that inventory positions are synchronized between suppliers, manufacturers, and customers using the same logic and timing rules.

As inventory changes due to receipts, production consumption, or shipments, updates flow electronically to trading partners without waiting for manual reports or end-of-day reconciliations. This shared visibility reduces the risk of stockouts, excess inventory, and last-minute expediting that erodes margins and disrupts operations.

Built-In Validation and Error Prevention

Inventory accuracy depends on more than counting—it depends on preventing bad data from spreading. Strong EDI inventory management software validates incoming and outgoing inventory data against predefined rules. Quantities, units of measure, item identifiers, and locations are checked before inventory updates are accepted or transmitted.

This validation protects downstream processes. Incorrect inventory data doesn’t make its way into production schedules, replenishment logic, or customer commitments. Over time, this reduces firefighting and builds confidence that inventory data can be trusted across departments.

Scalability and System Integration

As supply chains grow more complex, inventory management must scale with them. EDI inventory management software is designed to integrate with ERPs, WMS platforms, and other operational systems without creating brittle, one-off connections. New trading partners, additional warehouses, or higher transaction volumes can be added without redesigning the entire inventory process.

This scalability is especially important for manufacturers and suppliers managing multiple customers with different inventory visibility requirements. The software acts as a centralized control point, ensuring that inventory data remains consistent even as complexity increases.

Business Benefits of EDI Inventory Management—Measured and Real

The value of EDI inventory management becomes clearest when it’s tied to outcomes the business actually cares about. Beyond automation and connectivity, the real payoff shows up in accuracy, speed, and cost control across the supply chain.

Higher Inventory Accuracy and Fewer Discrepancies

One of the most immediate benefits of EDI in inventory management is improved accuracy. When inventory updates are exchanged electronically and validated automatically, companies eliminate many of the errors introduced by manual entry and delayed reporting. Inventory balances stay aligned between internal systems and trading partners, reducing the need for constant reconciliation and emergency corrections.

Over time, this accuracy compounds. Fewer discrepancies mean fewer surprises during production planning, fewer missed shipments, and greater confidence in inventory data across departments.

Reduced Manual Effort and Faster Response Times

Manual inventory updates consume time and introduce latency into decision-making. EDI inventory management software removes those bottlenecks by automating how inventory changes are communicated and processed. As receipts are posted, production consumes material, or shipments leave the dock, inventory positions update electronically without waiting for human intervention.

This speed matters when demand changes quickly. Planners and customer service teams can respond to shifts in requirements using current data rather than yesterday’s snapshot. The result is faster reaction times and less reliance on buffers or excess stock to compensate for uncertainty.

Improved Demand Planning and Replenishment

Accurate, timely inventory data is a prerequisite for effective planning. With EDI inventory systems feeding reliable inventory positions into ERP and planning tools, organizations can make better decisions about what to produce, what to reorder, and when to replenish.

Instead of reacting to shortages after they occur, teams can anticipate needs based on shared inventory visibility with customers and suppliers. This proactive planning reduces stockouts, minimizes expediting costs, and supports more stable production schedules.

Lower Carrying Costs and Less Excess Inventory

When inventory visibility improves, businesses no longer need to overstock as insurance against bad data. EDI inventory management supports leaner inventory strategies by providing confidence that what’s reported is accurate and current.

As a result, companies often see reduced carrying costs, less obsolete inventory, and better use of working capital. Inventory becomes a controlled asset rather than a risk buffer.

Stronger Trading Partner Collaboration

Finally, EDI inventory management strengthens relationships across the supply chain. When customers and suppliers share consistent inventory data, conversations shift from reactive problem-solving to coordinated planning. Expectations are clearer, commitments are more reliable, and performance improves on both sides.

How to Choose the Right EDI Inventory Management System

Not all EDI solutions are created equal, especially when it comes to inventory. Many organizations already have some form of EDI in place, yet still struggle with inaccurate inventory, delayed updates, or constant manual intervention. Choosing the right EDI inventory management system means looking beyond basic connectivity and focusing on how well the system supports real operational needs.

Start With Your Inventory Complexity

The first step is understanding your own environment. Inventory management looks very different for a single-site operation than it does for a multi-plant supplier serving multiple customers with different visibility requirements. Consider how many locations you manage, how often inventory changes, and how frequently trading partners expect updates.

An effective EDI inventory system should handle frequent inventory movements, multiple units of measure, and customer-specific rules without requiring manual workarounds. If your current setup relies heavily on spreadsheets or custom scripts to reconcile inventory data, that’s a clear sign the system isn’t doing enough.

Evaluate ERP and WMS Integration Depth

Inventory data only matters if it flows directly into the systems that drive execution. When evaluating EDI inventory management software, look closely at how it integrates with your ERP and warehouse management systems. Integration should be native and automated, not dependent on file drops or manual imports.

Strong integration ensures that inventory updates generated by production, receiving, and shipping processes are reflected accurately in outbound EDI messages. It also guarantees that inbound inventory data immediately supports planning, replenishment, and customer commitments.

Look for Validation and Exception Handling

Inventory errors are costly, but they’re also preventable. A reliable EDI inventory management system should validate inventory data before it’s accepted or transmitted. This includes checking quantities, item identifiers, locations, and timing against predefined business rules.

Just as important is visibility into exceptions. When inventory discrepancies occur, the system should surface them quickly and clearly so teams can take corrective action. Without this capability, issues often go unnoticed until they disrupt shipments or production schedules.

Assess Scalability and Trading Partner Support

Inventory requirements tend to grow more complex over time. New customers, additional warehouses, and higher transaction volumes can quickly strain systems that weren’t built to scale. EDI inventory management software should support onboarding new trading partners and expanding inventory visibility without extensive reconfiguration.

A scalable system allows organizations to grow without reintroducing manual processes or increasing the risk of data errors as complexity increases.

Align the System With Business Goals

Finally, the right EDI inventory management system should support your broader operational objectives. Whether your priority is reducing inventory carrying costs, improving on-time delivery, or supporting just-in-time production, the system should provide the visibility and control needed to achieve those goals.

Best Practices for Implementing EDI in Inventory Management

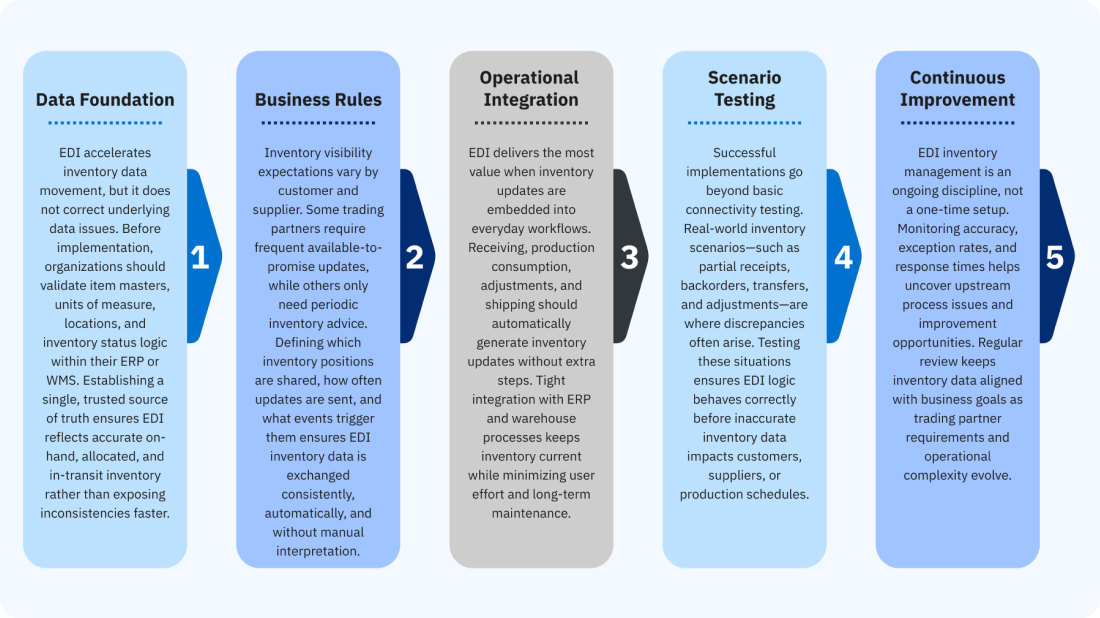

Implementing EDI in inventory management is as much about process alignment as it is about technology. Even the most capable EDI inventory management software can fall short if it’s layered onto broken workflows or inconsistent data practices. The following best practices help ensure that EDI becomes a long-term advantage rather than another system to maintain.

Begin With Clean, Trusted Inventory Data

EDI will move inventory data faster—but it won’t fix bad data. Before implementation, organizations should validate item masters, units of measure, location definitions, and inventory status logic inside their ERP or WMS. If on-hand quantities, allocations, or in-transit inventory aren’t reliable internally, those issues will simply be exposed more quickly through EDI.

Establishing a single source of truth for inventory is critical. EDI should reflect what the system of record says, not attempt to reconcile conflicting data across departments after the fact.

Define Inventory Business Rules Up Front

Inventory visibility often means different things to different trading partners. Some customers expect frequent updates of available-to-promise quantities, while others only require periodic inventory advice. Best-in-class EDI inventory management implementations clearly define which inventory positions are shared, how often updates are sent, and under what conditions inventory data is triggered.

These rules should be agreed upon early and built directly into the EDI inventory management system so that inventory data is exchanged consistently and automatically, without manual interpretation.

Integrate Inventory Updates Into Daily Operations

EDI works best when it’s embedded into normal operational workflows. Inventory updates should be generated as a natural outcome of receiving, production consumption, adjustments, and shipping—not as an extra step performed at the end of the day.

When EDI inventory management software is tightly integrated with ERP and warehouse processes, inventory visibility stays current without adding workload to operations teams. This reduces resistance to adoption and improves long-term reliability.

Test With Real Inventory Scenarios

Testing should go beyond basic connectivity. Effective implementations validate how the system handles real-world inventory scenarios such as partial receipts, backorders, location transfers, and inventory adjustments. These situations are where discrepancies often arise and where EDI logic must be precise.

Running scenario-based tests ensures that inventory updates behave as expected before they impact customers or suppliers.

Monitor, Measure, and Refine

EDI inventory management is not a “set it and forget it” initiative. Ongoing monitoring helps identify patterns such as frequent inventory adjustments, delayed updates, or recurring exceptions. These signals often point to upstream process issues that can be corrected to further improve accuracy and efficiency.

Regularly reviewing performance metrics—such as inventory accuracy, exception rates, and response times—keeps the system aligned with business goals as requirements evolve.

With strong implementation practices in place, EDI inventory management becomes a stable foundation for more advanced capabilities. In the next section, we’ll look at emerging trends and how EDI inventory systems are evolving to support increasingly data-driven supply chains.

Beyond the Basics: Advanced Trends in EDI Inventory Management

As supply chains become more interconnected and time-sensitive, EDI inventory management is evolving beyond traditional batch updates and static reporting. Modern organizations are using EDI as a foundation for more dynamic, data-driven inventory strategies that improve resilience and responsiveness.

Moving Toward Near–Real-Time Inventory Visibility

Historically, many EDI inventory systems relied on scheduled transmissions—daily or even weekly updates that reflected inventory status at a point in time. Today, the trend is toward near–real-time inventory visibility. Inventory updates are triggered by actual events such as receipts, production consumption, or shipments, rather than by a fixed schedule.

This shift allows trading partners to react faster to changes in demand or supply disruptions. When inventory positions are shared more frequently and consistently, planners can make decisions based on current conditions instead of lagging indicators.

Hybrid Models: EDI Working Alongside APIs

EDI remains the backbone for standardized, high-volume inventory communication, but many organizations are augmenting it with APIs for specific use cases. In these hybrid models, EDI continues to handle formal inventory advice and transactional integrity, while APIs support faster queries, dashboards, or internal analytics.

Rather than replacing EDI, APIs enhance how inventory data is consumed and visualized. The combination allows companies to preserve compliance and standardization while gaining flexibility in how inventory data is accessed and used internally.

Smarter Planning Using EDI Inventory Data

Inventory data exchanged through EDI is increasingly being fed into advanced planning and forecasting tools. By combining historical EDI inventory messages with demand patterns and production data, organizations can improve forecast accuracy and identify trends that were previously hidden.

This approach supports more proactive inventory strategies. Instead of reacting to shortages or excess after they occur, businesses can adjust production, replenishment, or allocation decisions earlier—reducing risk and cost.

Greater Focus on Exception-Driven Management

As inventory systems become more automated, attention is shifting from routine updates to exceptions. Modern EDI inventory management software is designed to highlight unusual conditions, such as sudden inventory drops, repeated adjustments, or mismatches between reported and actual availability.

By focusing on exceptions rather than normal activity, teams can spend less time monitoring data and more time resolving the issues that truly impact performance.

Preparing for More Complex Supply Chains

Global sourcing, multi-tier supplier networks, and just-in-time manufacturing all place greater demands on inventory visibility. EDI inventory management systems are evolving to support these complexities by handling multiple locations, tiers, and inventory states without sacrificing accuracy or performance.

Organizations that invest in scalable, flexible EDI inventory management today are better positioned to adapt as supply chains continue to grow more interconnected.

Conclusion: Turning Inventory Into a Competitive Advantage With EDI

Inventory problems rarely exist in isolation. They ripple into production delays, missed shipments, customer dissatisfaction, and rising costs. EDI inventory management addresses these challenges by replacing fragmented, manual updates with structured, automated inventory communication that keeps every part of the supply chain aligned.

When implemented correctly, EDI in inventory management delivers more than visibility. It creates confidence—confidence that inventory data is accurate, current, and trusted across internal teams and external trading partners. An effective EDI inventory system ensures that what’s on hand, what’s committed, and what’s in motion are clearly understood, enabling better planning and fewer disruptions.

The real differentiator is software. The right EDI inventory management software transforms raw inventory messages into actionable insight, validates data before it causes downstream issues, and integrates inventory visibility directly into ERP, warehouse, and production workflows. This is what allows organizations to move from reactive firefighting to proactive inventory control.

As supply chains continue to demand greater speed, accuracy, and coordination, EDI-driven inventory management is no longer optional. Companies that invest in scalable, well-integrated EDI inventory systems position themselves to reduce risk, control costs, and respond faster to change—turning inventory from a constraint into a strategic advantage.

If your organization is still managing inventory through delayed updates, manual reconciliation, or disconnected systems, now is the time to evaluate whether your current approach can support where your supply chain is headed next.

Take Control of Inventory Accuracy With Automotive-Grade EDI

Struggling with delayed inventory updates, manual reconciliation, or inconsistent visibility across customers and plants? AIM helps automotive suppliers use EDI inventory management to maintain accurate, real-time inventory data across the supply chain—fully integrated with ERP, shipping, and production workflows.

Schedule a conversation to see how AIM AutoSys, AIM AutoCOR, or AIM Vision ERP can support reliable inventory visibility, reduce errors, and strengthen compliance across your operations.