Future Trends in Supply Chain Management

Supply chain management is entering a new era—one defined by rapid technological innovation, heightened customer expectations, and increasing pressure to operate with greater resilience and transparency. What were once linear, predictable supply chains are now complex, data-driven ecosystems that must adapt in real time to disruptions, demand shifts, and evolving regulatory requirements.

As manufacturers and suppliers look ahead, understanding future trends in supply chain management is no longer optional—it’s a competitive necessity. From AI-driven forecasting and real-time visibility to sustainability initiatives and advanced supply chain software, today’s supply chain management trends are reshaping how organizations plan, produce, ship, and collaborate across global networks.

In this article, we’ll explore the latest trends in supply chain management and the supply chain industry trends that will define the next several years. We’ll also examine how modern supply chain software trends are enabling companies—especially automotive and industrial suppliers—to move from reactive operations to proactive, intelligent supply chains built for resilience, compliance, and long-term growth.

Whether you’re navigating OEM mandates, managing multi-tier supplier networks, or evaluating new technology investments, these insights will help you prepare for what’s next in the evolving world of supply chain management.

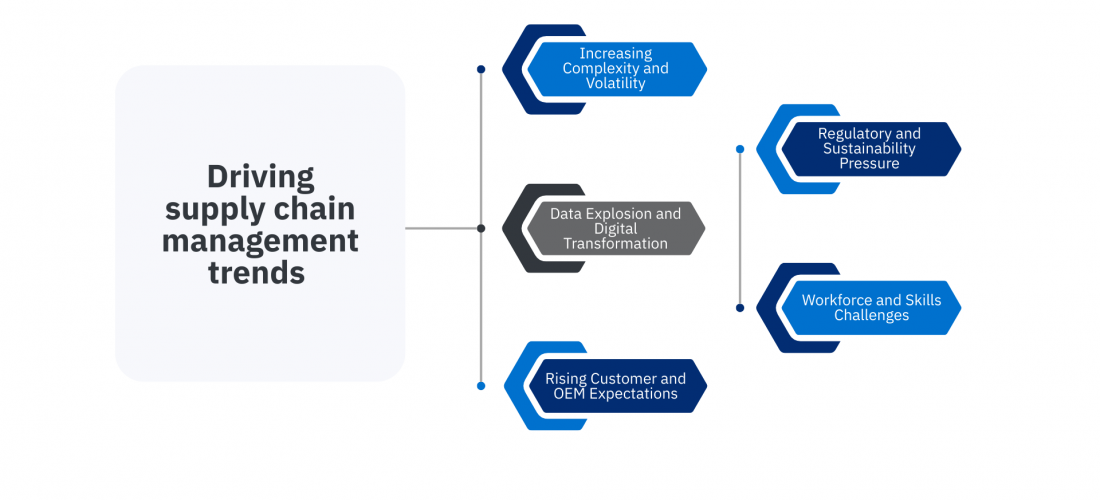

The Big Picture: Key Drivers Shaping Supply Chain Management Trends

To understand the future of supply chain management, it’s important to first look at the forces driving change across the global supply chain landscape. Today’s supply chain management trends are not emerging in isolation—they are the result of economic pressure, technology acceleration, regulatory demands, and rising expectations from customers and OEMs alike.

Several core drivers are shaping the latest trends in supply chain management:

1. Increasing Complexity and Volatility

Global supply chains are more interconnected than ever, but that connectivity comes with risk. Geopolitical instability, labor shortages, transportation disruptions, and supplier capacity constraints have made volatility the new normal. As a result, organizations are prioritizing resilience, flexibility, and scenario planning as foundational supply chain capabilities.

2. Data Explosion and Digital Transformation

Modern supply chains generate massive volumes of data—from forecasts and releases to inventory movements and shipment confirmations. The challenge is no longer data availability, but data usability. This shift is fueling demand for advanced analytics, real-time visibility, and integrated supply chain software trends that can turn raw data into actionable insights across planning, production, and logistics.

3. Rising Customer and OEM Expectations

OEMs and Tier 1 customers now expect near-perfect performance: accurate ASNs, AIAG-compliant labeling, real-time shipment visibility, and strict adherence to delivery windows. These requirements are pushing suppliers to adopt smarter, more automated systems that reduce manual effort while improving accuracy and compliance.

4. Regulatory and Sustainability Pressure

Environmental regulations, traceability requirements, and sustainability initiatives are becoming embedded into supply chain strategy. Companies must now track material origin, reduce waste, and demonstrate compliance—making digital traceability and transparent reporting essential components of modern supply chain management.

5. Workforce and Skills Challenges

As experienced supply chain professionals retire and operations become more technology-driven, organizations face a growing skills gap. Future-ready supply chains must balance automation with usability, ensuring systems support both efficiency and workforce adoption.

Together, these drivers are redefining supply chain industry trends, pushing organizations away from reactive, siloed processes toward connected, intelligent supply chains. In the next section, we’ll explore the most impactful trends emerging from these forces—and how they are transforming supply chain operations in real terms.

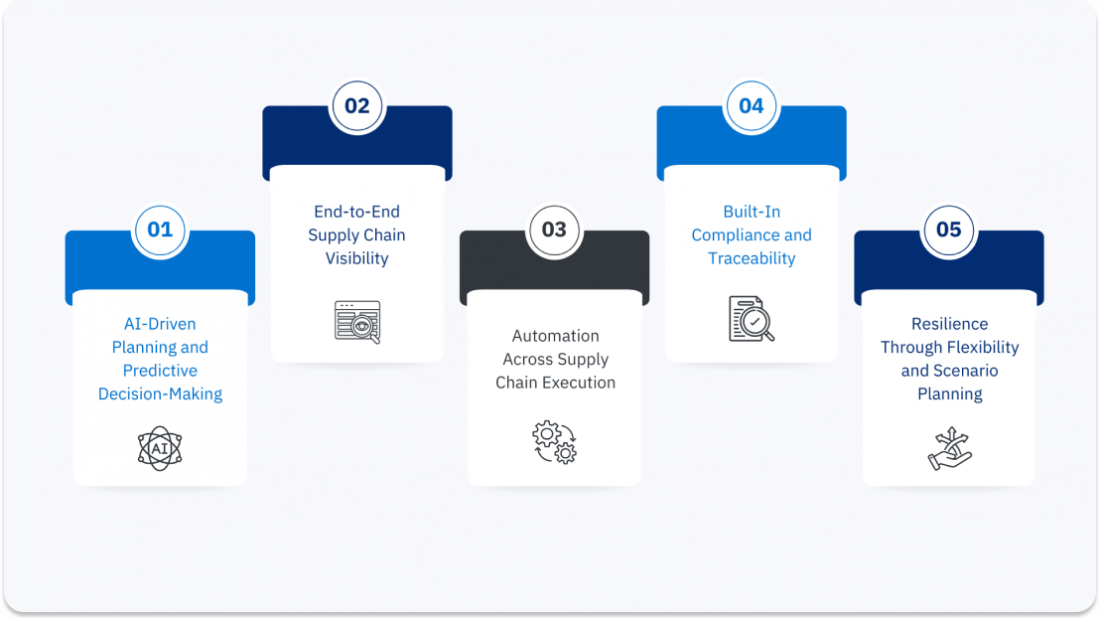

Leading Supply Chain Management Trends to Watch

As supply chains evolve to meet new operational and market demands, several clear patterns are emerging. These supply chain management trends reflect a shift toward smarter, more connected, and more resilient operations—enabled by technology and driven by the need for accuracy, speed, and compliance.

Below are the most impactful future trends in supply chain management organizations should be preparing for now.

1. AI-Driven Planning and Predictive Decision-Making

Artificial intelligence is rapidly moving from experimentation to execution in supply chain environments. AI and machine learning are now being applied to:

- Demand forecasting and release smoothing

- Predictive risk identification and disruption alerts

- Automated decision support for inventory and production planning

Instead of reacting to shortages or late shipments, organizations can proactively adjust schedules and resources. This shift marks a major evolution in supply chain software trends, where systems don’t just report what happened—they recommend what to do next.

2. End-to-End Supply Chain Visibility

One of the most consistent supply chain industry trends is the push for full visibility—from raw material suppliers to final delivery. Companies are investing in systems that provide real-time insight into:

- Inventory levels across locations

- Production status and constraints

- In-transit shipments and delivery confirmations

This level of transparency reduces surprises, improves customer communication, and supports tighter just-in-time operations—especially in industries like automotive manufacturing, where timing and accuracy are critical.

3. Automation Across Supply Chain Execution

Automation is no longer limited to warehouses. Today’s latest trends in supply chain management include automation across:

- Order processing and release management

- ASN creation and validation

- Barcode labeling and shipment verification

By reducing manual touchpoints, organizations lower error rates, speed up execution, and free teams to focus on exception management instead of repetitive tasks.

4. Built-In Compliance and Traceability

Compliance is becoming a built-in requirement, not an afterthought. Modern supply chains must support:

- Traceability at the lot, container, and shipment level

- Compliance with industry standards and customer mandates

- Digital audit trails for quality and regulatory reviews

This trend is driving adoption of systems that embed compliance logic directly into daily operations—making it easier to meet requirements without slowing down the business.

5. Resilience Through Flexibility and Scenario Planning

Resilience is now a core performance metric. Organizations are redesigning supply chains to support:

- Multi-sourcing strategies

- Dynamic rerouting and expedited shipping

- Scenario modeling for demand and supply disruptions

Rather than optimizing solely for cost, today’s supply chain trends prioritize continuity and adaptability—ensuring operations can respond quickly when conditions change.

Together, these trends illustrate how supply chain management is shifting from reactive execution to intelligent orchestration. In the next section, we’ll take a closer look at how supply chain software trends are enabling these capabilities—and what to look for when evaluating modern supply chain technology.

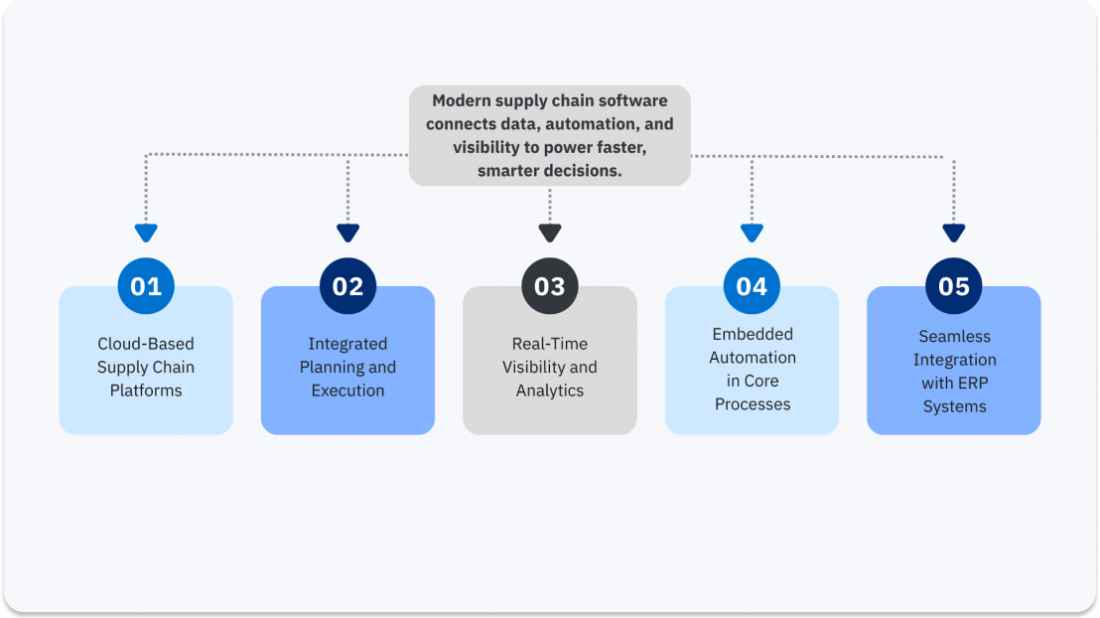

Supply Chain Software Trends Enabling the Next Generation of Supply Chains

Software innovation sits at the center of today’s supply chain management trends. As supply chains become more data-intensive and interconnected, organizations are relying on modern supply chain software to improve visibility, automate execution, and respond faster to change. The following supply chain software trends are shaping how supply chains operate today—and how they will evolve in the years ahead.

Cloud-Based Supply Chain Platforms

One of the most impactful latest trends in supply chain management is the continued shift toward cloud-based supply chain platforms. Cloud technology allows organizations to access real-time supply chain data across plants, warehouses, and trading partners without the constraints of traditional on-premise infrastructure. This accessibility is especially important for distributed operations that require consistent visibility across regions and facilities.

Beyond accessibility, cloud platforms support scalability and agility. As supply chain requirements change—whether due to growth, new customers, or regulatory mandates—cloud-based systems can be updated and expanded more quickly than legacy environments. This enables organizations to respond faster to disruptions, collaborate more effectively with partners, and maintain continuity without heavy IT overhead.

Cloud Platform Use: 69% of large enterprises in logistics are using cloud-driven supply chain platforms, showing broad adoption of cloud technology across distribution and fulfillment.

Source: SQMagazine

Integrated Planning and Execution

Disconnected planning and execution systems are no longer sustainable in today’s fast-moving supply chains. Modern supply chain software increasingly unifies demand planning, production scheduling, inventory management, and shipping into a single operational environment. This integration ensures that plans are grounded in real execution constraints and that execution reflects the most current demand signals.

By eliminating silos and manual handoffs, integrated systems improve data accuracy and reduce latency between planning decisions and operational action. This capability is a critical enabler of future trends in supply chain management, particularly those focused on agility, responsiveness, and resilience in just-in-time and high-mix manufacturing environments.

Impact of AI & Big Data: Integration of AI and big data analytics has been shown to reduce inventory costs by up to 30% and improve forecasting accuracy by roughly 23%, highlighting the quantifiable benefits of analytics in supply chain operations.

Source: worldmetrics

Real-Time Visibility and Analytics

Visibility has evolved from a competitive advantage into a baseline requirement. Advanced analytics and real-time dashboards are now core components of modern supply chain software, providing continuous insight into inventory levels, production status, and shipment activity. Instead of waiting for end-of-day or end-of-week reports, teams can see what’s happening as it happens.

This real-time insight allows organizations to identify risks earlier, manage exceptions more effectively, and take corrective action before issues escalate. Over time, these analytics also support continuous improvement by highlighting trends, bottlenecks, and performance gaps—reinforcing broader supply chain industry trends around data-driven decision-making.

Predictive Capabilities: By 2025, nearly half (52%) of supply chain organizations report using predictive analytics to forecast demand and optimize operations.

Source: worldmetrics

Embedded Automation in Core Processes

Automation is no longer an add-on—it is increasingly embedded directly into core supply chain workflows. From order processing and release management to labeling, shipment verification, and ASN generation, modern systems automate repetitive tasks while enforcing predefined business rules and compliance requirements.

This embedded approach reduces reliance on manual intervention, lowers error rates, and ensures consistency across high-volume operations. As supply chains scale and transaction volumes increase, embedded automation enables organizations to maintain performance and accuracy without proportionally increasing headcount—an essential shift in supply chain management trends focused on efficiency and control.

Seamless Integration with ERP and Partner Systems

As supply chains span multiple systems and organizations, interoperability has become essential. Leading supply chain software is designed to integrate cleanly with ERP platforms and external partner systems, allowing data to flow consistently across planning, production, finance, and logistics.

This seamless integration supports shared visibility and collaboration across the supply chain network, reducing friction between internal teams and external partners. It also accelerates customer and supplier onboarding, simplifies compliance with partner-specific requirements, and strengthens overall execution—key outcomes driving many future trends in supply chain management.

This evolution in supply chain software trends is enabling organizations to shift from reactive execution to intelligent, connected supply chains. In the next section, we’ll look beyond technology to explore broader supply chain industry trends—including sustainability, workforce transformation, and new operating models shaping the future of supply chain management.

Broader Supply Chain Industry Trends Shaping the Future

Beyond technology, structural and operational shifts are redefining how supply chains are designed and managed. These supply chain industry trends reflect changing expectations from customers, regulators, and the workforce—and they influence how organizations prioritize investments, partnerships, and operating models.

Sustainability Becomes a Core Supply Chain Objective

Sustainability has moved well beyond a corporate initiative or marketing message to become an operational requirement. Organizations are increasingly expected to reduce waste, improve material traceability, and demonstrate environmental responsibility across their supply chains. Customers, OEMs, and regulators alike are demanding greater transparency into sourcing, production, and logistics practices.

As a result, sustainability is now being embedded directly into planning, sourcing, and logistics decisions. Rather than treating environmental metrics as separate reporting exercises, companies are integrating them into day-to-day supply chain operations. This shift is a defining element of future trends in supply chain management, as sustainability increasingly influences supplier selection, network design, and performance measurement.

Strategic Supply Chain Priorities: Industry analyses consistently list sustainability, resilience, and workforce capability as among the top strategic priorities for 2025 supply chain leaders.

Source: ascm

Resilience Over Pure Cost Optimization

For decades, supply chains were optimized primarily for cost efficiency. Today, that mindset is changing. Ongoing disruptions—from geopolitical instability to transportation bottlenecks and supplier failures—have exposed the risks of overly lean, single-threaded networks. In response, resilience is becoming a primary design principle.

Organizations are rebalancing cost considerations with flexibility, reliability, and risk mitigation. Multi-sourcing strategies, buffer capacity, and contingency planning are now central themes in supply chain management trends, particularly for manufacturers operating in just-in-time environments where disruptions can quickly halt production. The ability to absorb shocks and recover quickly is increasingly viewed as a competitive advantage, not a trade-off.

Disruptions Impact: Nearly 94% of companies report revenue impact from supply chain disruptions, demonstrating why resilience and flexibility are now top strategic priorities.

Source: procurementtactics

Regionalization and Nearshoring Strategies

Another important supply chain trend is the shift toward regionalization and nearshoring. While global supply chains remain essential, many organizations are deliberately reducing reliance on distant suppliers in favor of more regional networks. This approach helps shorten lead times, improve responsiveness, and reduce exposure to global transportation and geopolitical risks.

Regionalization is especially relevant in highly regulated industries where delivery reliability, traceability, and compliance are critical. By balancing global reach with regional execution, companies can create more stable and predictable supply chains while maintaining the flexibility needed to respond to market changes.

Workforce Transformation and Knowledge Retention

As experienced supply chain professionals retire, organizations face increasing pressure to retain institutional knowledge while onboarding new talent. This demographic shift is influencing latest trends in supply chain management, driving a focus on standardized processes, system-driven workflows, and intuitive tools that reduce dependence on tribal knowledge.

Future-ready supply chains must support both automation and human decision-making. Systems that guide users through best practices, enforce business rules, and surface actionable insights help close the skills gap while enabling faster ramp-up for new employees. Workforce transformation is no longer just an HR issue—it is a core supply chain concern.

Stronger Collaboration Across the Supply Chain Network

Supply chains are increasingly being viewed as collaborative ecosystems rather than linear handoffs between organizations. OEMs, suppliers, logistics providers, and technology partners are sharing more data and aligning processes to improve performance across the network. This shift reflects a growing recognition that supply chain outcomes are interdependent.

Stronger collaboration supports better forecasting, faster issue resolution, and more resilient operations. It also strengthens relationships across the supply chain, creating shared accountability and trust. This collaborative mindset is a key characteristic of modern supply chain industry trends, enabling organizations to respond more effectively to complexity and change.

Together, these industry-level shifts are redefining what effective supply chain management looks like. In the next section, we’ll explore how organizations can translate these supply chain management trends into practical strategies—and what leaders should focus on to prepare their supply chains for what’s ahead.

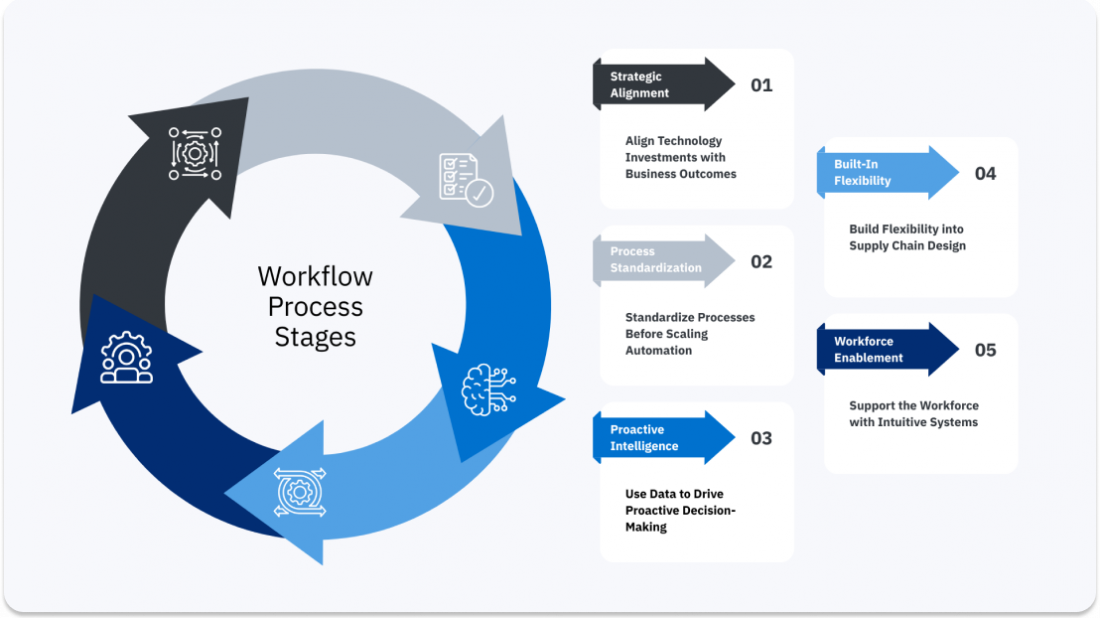

Turning Supply Chain Trends into Actionable Strategy

Understanding the future trends in supply chain management is only the first step. The real advantage comes from translating these trends into practical, measurable actions that improve daily operations while positioning the organization for long-term resilience and growth.

Align Technology Investments with Business Outcomes

As supply chain software trends continue to evolve, organizations must be disciplined about where and how they invest. The most effective supply chain leaders do not adopt technology simply because it is new or innovative; instead, they prioritize systems that directly support business-critical outcomes such as on-time delivery, inventory accuracy, compliance performance, and execution reliability.

This alignment requires a clear understanding of operational pain points and strategic priorities. Whether the challenge is managing demand variability, meeting customer and regulatory mandates, or coordinating activity across multiple locations, technology investments should be evaluated based on their ability to solve real-world problems. When technology decisions are anchored to measurable outcomes, organizations avoid unnecessary complexity and ensure that digital transformation delivers tangible value.

Standardize Processes Before Scaling Automation

Automation delivers its greatest impact when it is built on consistent, well-defined processes. Organizations adopting the latest trends in supply chain management recognize that automating fragmented or inconsistent workflows often amplifies inefficiencies rather than eliminating them.

Before scaling automation, leading companies focus on aligning core supply chain processes across plants, departments, and partners. Standardized workflows reduce exceptions, simplify training, and create a stable foundation for automation to succeed. This approach ensures that automation reinforces best practices and drives repeatable performance instead of introducing new sources of variability.

Use Data to Drive Proactive Decision-Making

One of the most meaningful supply chain management trends is the shift from reactive problem-solving to proactive control. Rather than responding to issues after they occur, organizations are increasingly leveraging real-time data and analytics to anticipate disruptions before they impact operations.

By monitoring inventory levels, production status, and shipment activity in near real time, supply chain teams can identify emerging risks such as material shortages, capacity constraints, or delivery delays. This proactive visibility allows earlier intervention, better prioritization, and lower overall cost of response. Over time, data-driven decision-making becomes a core capability that strengthens resilience and supports continuous improvement.

Build Flexibility into Supply Chain Design

Future-ready supply chains are designed with change in mind. Instead of relying on rigid networks optimized for a single scenario, organizations are building flexibility into sourcing, production, and logistics strategies. This includes supporting alternate suppliers, dynamic routing options, and scenario planning capabilities that allow the supply chain to adapt as conditions change.

This flexibility is a direct response to supply chain industry trends emphasizing resilience over pure efficiency. By designing supply chains that can absorb disruption and adjust quickly, organizations transform resilience from a theoretical concept into a practical operational advantage.

Support the Workforce with Intuitive Systems

Technology adoption is only effective if the workforce can use it confidently and consistently. As supply chain teams evolve and experienced professionals retire, organizations face increasing pressure to reduce reliance on institutional knowledge and manual workarounds.

To address this challenge, companies are investing in systems that guide users through best practices, enforce business rules, and surface actionable insights at the point of decision. These intuitive, user-centric systems shorten learning curves, reduce errors, and enable new employees to contribute more quickly. This human-centered approach is becoming a defining characteristic of sustainable supply chain trends, ensuring that technology strengthens—not complicates—the work people do every day.

By turning insight into execution, organizations can move beyond trend awareness and create supply chains that are more resilient, compliant, and responsive. In the next section, we’ll look ahead to what these supply chain management trends mean for the future—and how leaders can prepare their organizations for what comes next.

What the Future of Supply Chain Management Looks Like

As the pace of change accelerates, the future of supply chain management will be defined less by isolated improvements and more by how well organizations connect strategy, technology, and execution. The future trends in supply chain management point to supply chains that are not only faster and more automated, but also more intelligent, resilient, and adaptable.

From Reactive Operations to Intelligent Supply Chains

Traditional supply chains have relied heavily on after-the-fact reporting and manual intervention. Moving forward, leading organizations will operate supply chains that continuously sense, analyze, and respond to change. Real-time data, embedded analytics, and automation will allow supply chain teams to anticipate disruptions, adjust plans dynamically, and make decisions with greater confidence. This shift represents one of the most meaningful supply chain management trends shaping the years ahead.

Technology as a Strategic Enabler, Not a Differentiator

As advanced tools become more widely available, technology alone will no longer differentiate supply chain leaders. Instead, competitive advantage will come from how effectively organizations deploy supply chain software to support their unique business models, compliance requirements, and customer expectations. The most successful companies will align supply chain software trends with clear operational goals rather than treating technology as a standalone initiative.

Compliance, Visibility, and Trust as Baseline Expectations

Future supply chains will be built on transparency and trust. Customers, OEMs, and regulators will increasingly expect accurate data, end-to-end traceability, and consistent execution. Meeting these expectations will require systems and processes that embed compliance and visibility into everyday operations—making them standard capabilities rather than reactive fixes. This evolution is already evident across supply chain industry trends.

Preparing for What’s Next

The organizations best positioned for the future are those taking action today. By investing in connected systems, standardizing processes, and empowering teams with actionable insights, companies can turn today’s latest trends in supply chain management into long-term operational strength.

The future of supply chain management is not about predicting the next disruption—it’s about building supply chains that are ready for whatever comes next.

Conclusion: Preparing for the Next Era of Supply Chain Management

The pace of change across global supply chains shows no signs of slowing. As the future trends in supply chain management continue to unfold, one thing is clear: supply chains that rely on manual processes, fragmented systems, and reactive decision-making will struggle to keep up. Those that embrace connectivity, automation, and intelligence will be positioned to lead.

The latest trends in supply chain management—from advanced software platforms and real-time visibility to resilience-focused network design—are reshaping how organizations plan, execute, and collaborate. These supply chain management trends are not about chasing innovation for its own sake, but about building supply chains that are accurate, compliant, and adaptable in the face of constant change.

For manufacturers and suppliers, especially those operating in highly regulated and fast-moving environments, the opportunity lies in turning awareness into action. By aligning technology investments with operational goals, standardizing processes, and empowering teams with better data, organizations can transform today’s supply chain software trends into long-term competitive advantage.

The future of supply chain management belongs to organizations that act now—building supply chains designed not just to survive disruption, but to perform consistently, scale efficiently, and support growth for years to come.

Ready to turn supply chain trends into real results?

Talk with an AIM expert to see how automotive-focused EDI, ERP, and supply chain automation can help you improve visibility, compliance, and execution.